Refractory Ceramic Fiber

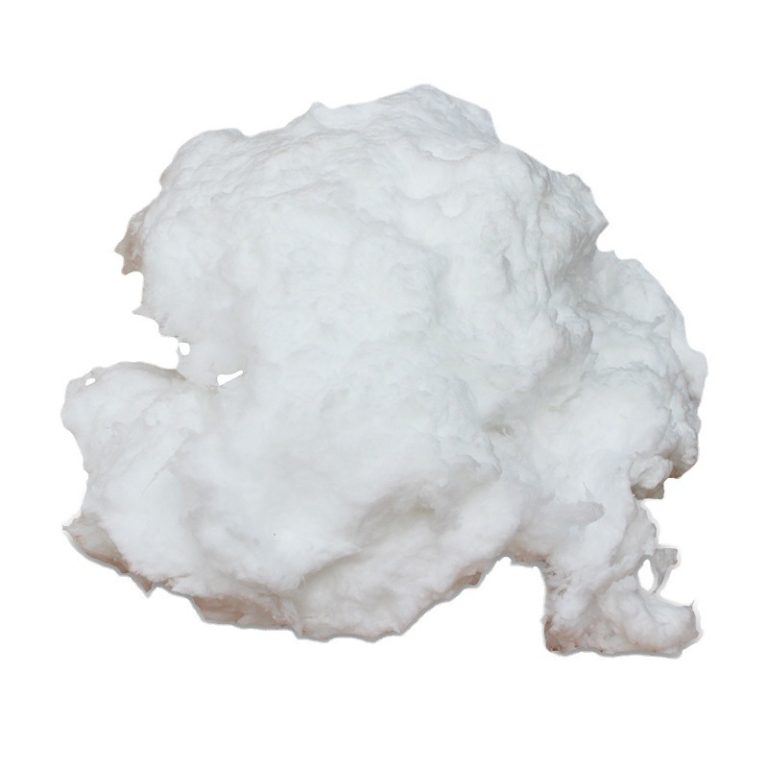

Ceramic fiber spinning cotton is made by melting high-purity raw materials at high temperature and using spinning method. The product has uniform diameter and white color.The physical property like refractory and insulation keep same when meet with oil,water or steam.

Ceramic fiber blanket/ felt/ board/ paper/ cloth/ rope and other ceramic fiber products can be produced by bulk through further processing. Hengrui ceramic fiber bulk is a kind of insulating materials which has these characteristics, such as light-weight, anti-oxidation, low thermal conductivity, softness, anti-corrosion, low heat capacity, sound insulation and so on.

| Spinning Bulk Fiber | HR1050C-BF | HR1260ST-BF | HR1260HP-BF | HR1350HA-BF | HR1400LZ-BF | HR1430HZ-BF | HR1500Cr-BF | HR1600PCF-BF | |

| Max·Service Temp. | 1050 | 1260 | 1260 | 1350 | 1400 | 1430 | 1500 | 1600 | |

| Shot Content(%)(θ≥0.212mm) | ≤22 | ≤22 | ≤20 | ≤20 | ≤18 | ≤18 | ≤20 | ≤3 | |

| Fiber Diameter(um) | 3-5 | 2-4 | 3-5 | 2-4 | 3-5 | 3-5 | 3-5 | 3-6 | |

| Chemical Composition(%) | Al2O3 | ≥38 | ≥42 | ≥45 | 52-55 | ≥37 | ≥37 | ≥37 | ≥70 |

| Chemical Composition(%) | Al2O3+SiO2 | ≥97.0 | ≥98.0 | ≥98.0 | ≥98.0 | ≥92 | ≥83 | ≥93 | ≥99 |

| Chemical Composition(%) | ZrO2 | - | - | - | - | 5-7 | 15-17 | - | - |

| Chemical Composition(%) | Cr2O3 | - | - | - | - | - | - | 3-5 | - |

| Chemical Composition(%) | Others | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.0 |

| Package | Packing in bags or cartons,20kg/ bag or 10kg/ carton | ||||||||

| Recommended using temperature: In oxidizing or neutral atmosphere, 100 ~250℃ lower than the maximum service temperature, In reductive atmosphere, 200 ~350℃ lower than the maximum service temperature. | |||||||||

Filling sealing and insulation at high temperatures(kiln car, pipeline, kiln door, etc.)

Expansion joint filler material for ceramic fiber board ,paper and vacuum formed shapes.

Thermal insulation filing material for small corner.

Expansion joint filler material for firebricks and castable.