In the modern metallurgical industry, thermal efficiency and operational costs are the two pillars of competitiveness. Ladle preheaters (ladle hoods) are critical in preparing ladles for molten steel or iron. Traditionally, these were lined with heavy castables or refractory bricks. However, the industry is shifting toward Ceramic Fiber Modules to achieve superior insulation and faster cycle times.

Ladle preheaters operate under extreme conditions, facing rapid temperature fluctuations and high-velocity gas burners. Ceramic fiber modules (made from high-purity alumina-silica materials) offer a lightweight, high-performance alternative to traditional dense refractories.

One of the primary reasons for switching to a fiber-lined ladle hood is the reduction in heat loss. Ceramic fiber has significantly lower thermal conductivity than refractory bricks. This ensures that the heat generated by the burners is reflected back into the ladle rather than being absorbed or lost through the hood casing.

Unlike heavy bricks that store a massive amount of heat (thermal mass), ceramic fiber modules have low heat storage capacity. This allows the ladle preheater to reach the target temperature faster and cool down quickly for maintenance, significantly increasing the "turnaround" speed of ladles in the plant.

Steel plants are violent thermal environments. Traditional refractories often crack or spall due to rapid heating and cooling. Ceramic fiber modules are flexible and resilient, making them virtually immune to thermal shock.

When selecting ceramic fiber modules for ladle preheating applications, the temperature rating and density are crucial.

| Feature | Standard Fiber Module | High-Zirconium Fiber Module |

| Classification Temp | 1260°C (2300°F) | 1430°C (2600°F) |

| Continuous Use Temp | Up to 1050°C | Up to 1230°C |

| Density | 220 kg/m³ | 220 kg/m³ |

| Common Application | Iron Ladle Preheaters | Steel Ladle Preheaters (High Temp) |

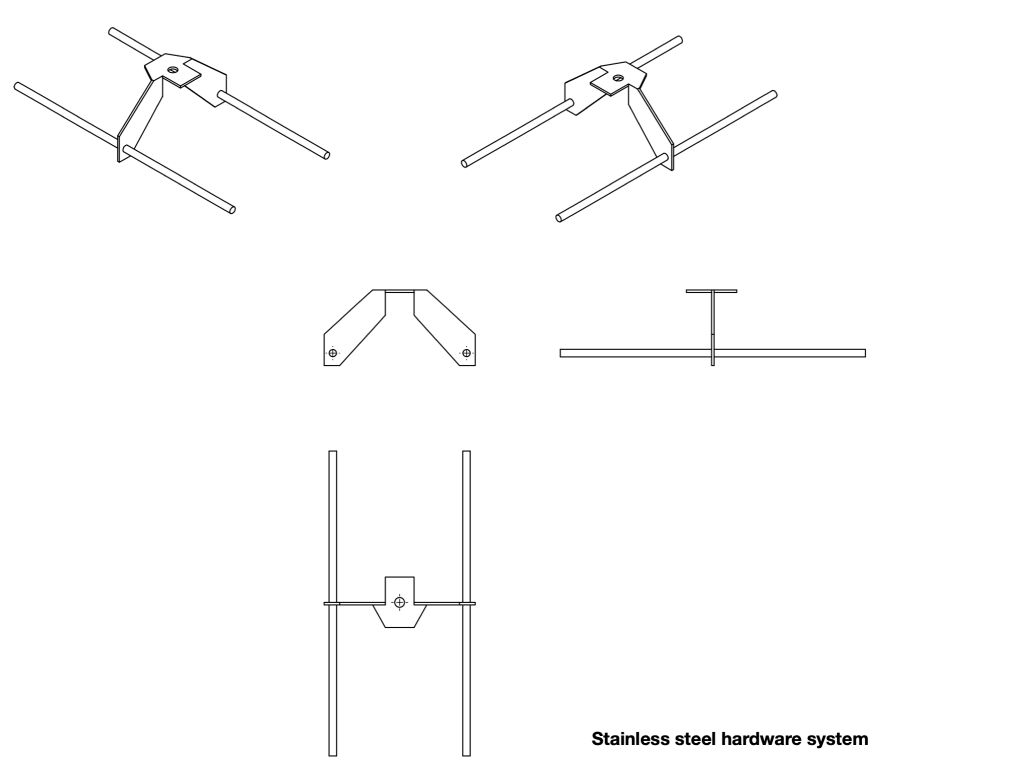

For ladle hoods, the pre-compressed folded module is the industry standard. These modules are compressed during manufacturing and held by plastic straps. Once installed via an internal anchoring system, the straps are cut, and the fiber expands.

While ceramic fiber is highly efficient, it is susceptible to mechanical damage and high-velocity gas erosion. To extend the life of your ladle hood lining, consider:

Upgrading your ladle preheater with Ceramic Fiber Modules is a proven strategy to reduce fuel consumption, lower shell temperatures, and improve the lifespan of your equipment. For steel mills looking to meet carbon reduction targets, fiber lining is no longer an option—it is a necessity.