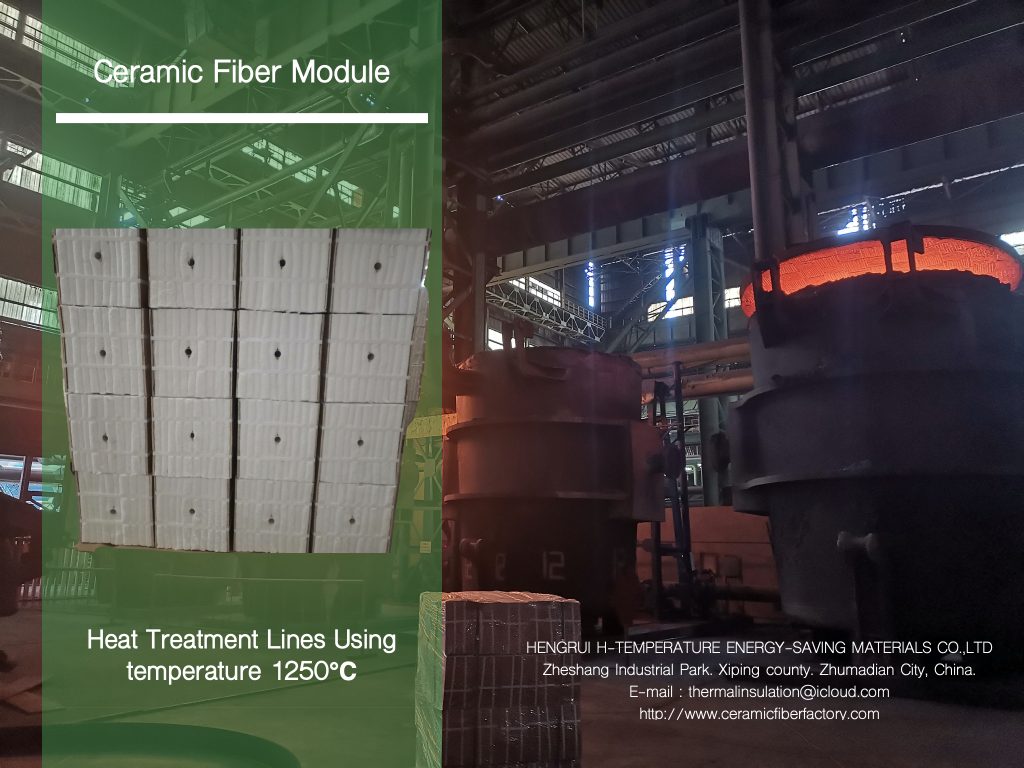

HENGRUI High-Temperature successfully implemented a zirconia ceramic fiber module lining system for a steel ladle preheating project. The solution provided exceptional thermal insulation, high installation efficiency, and significant energy savings, ensuring long-term operational reliability and reduced maintenance downtime.

1. Lightweight & Low Thermal Conductivity

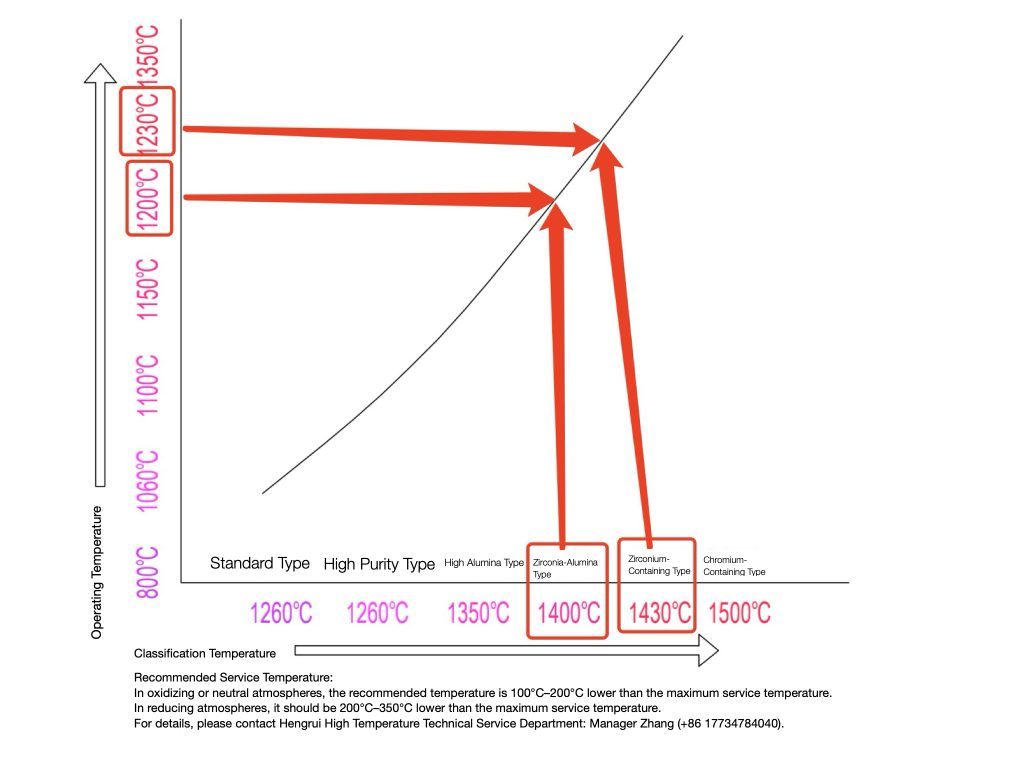

The zirconia ceramic fiber module provides excellent insulation performance, with extremely low heat conductivity and absorption. This results in reduced energy loss and improved furnace efficiency.

Pre-compressed modules automatically expand after installation, filling all joints and eliminating gaps, which enhances the overall sealing and integrity of the furnace lining.

Modular design and pre-set welding points allow rapid assembly—up to 1,000 standard modules can be installed within 7–10 days, greatly reducing construction time.

Zirconia fiber demonstrates exceptional structural stability under rapid temperature fluctuations, extending the service life of the furnace lining.

HENGRUI offers various anchor solutions tailored to different furnace types, temperature ranges, and operating conditions:

This anchoring system ensures secure fixing of ceramic fiber modules and consistent thermal insulation performance throughout the furnace lining.

After commissioning, the system achieved the following results:

✅ Significant reduction in heat loss

✅ Energy efficiency improvement by 15–30%

✅ Enhanced lining integrity and extended maintenance cycle

✅ Outer shell temperature below ambient +45°C

HENGRUI’s zirconia ceramic fiber module lining solution reflects the company’s commitment to energy-saving technology, advanced refractory design, and sustainable industrial innovation.