Project Name: Pre-Oxidation Furnace & Carbonization Furnace Lining Project

Application: PAN-Based Carbon Fiber Production Line, where the production furnace plays a crucial role.

Energy Efficiency: 15–30% improvement compared with traditional refractory brick linings

Construction Time: 7–10 days for standard-size furnace lining

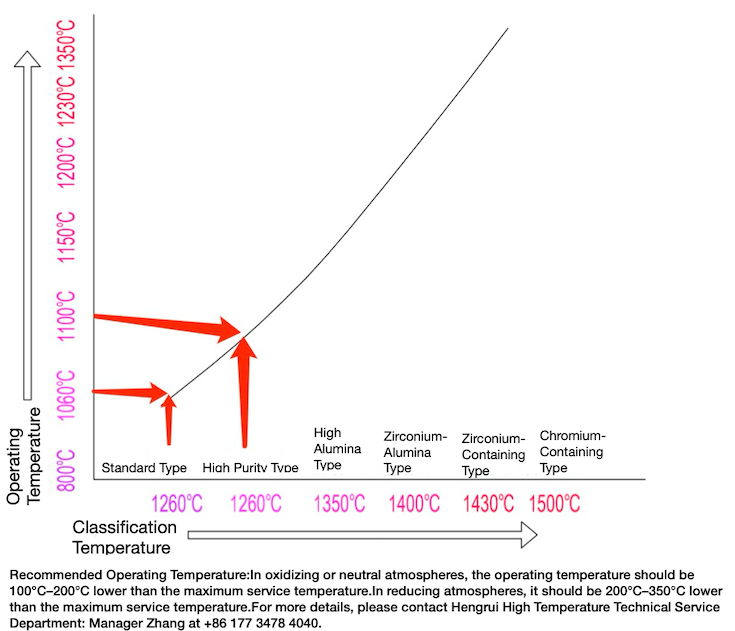

Refractory Standard: GB/T 3003-2017

Carbon fiber felt is a high-performance material made from carbonized fibers derived from polyacrylonitrile (PAN), pitch, viscose, or phenolic fibers.

Among these, PAN-based carbon fiber is the most widely used, fastest growing, and most mature in industrial applications — accounting for the majority of the global carbon fiber market, requiring specific production furnaces.

With global PAN-based carbon fiber production capacity exceeding 36,500 tons, it has become the second most important high-performance fiber after aramid. As a dual-use material serving both civilian and defense industries, PAN-based carbon fiber has been identified by China as a strategic high-tech material and a nationally supported new material for industrial development, often involving specialized carbon fiber production furnaces.

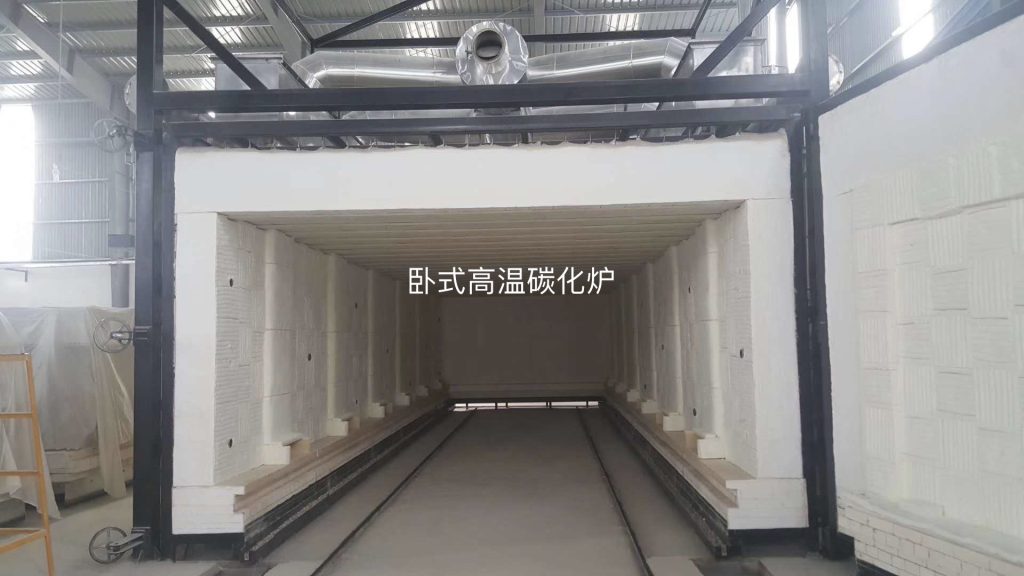

HENGRUI High Temperature provided a refractory fiber lining system for a pre-oxidation and carbonization furnace used in the production of PAN-based carbon fibers. These furnaces are integral to the production process.

Key Technical Specifications

Maximum Operating Temperature: 1000°C

Normal Working Temperature: 800°C

Heating Method: Electric alloy heating (Cr20Ni80 / 0Cr27Al7Mo2)

External Shell Temperature: ≤ ambient temperature +45°C

This equipment includes pre-oxidation furnaces, carbonization furnaces, and regenerative thermal oxidizers (RTO) — all designed for high-temperature, energy-efficient, and stable operation, crucial in PAN-Based Carbon Fiber Production Furnace processes.

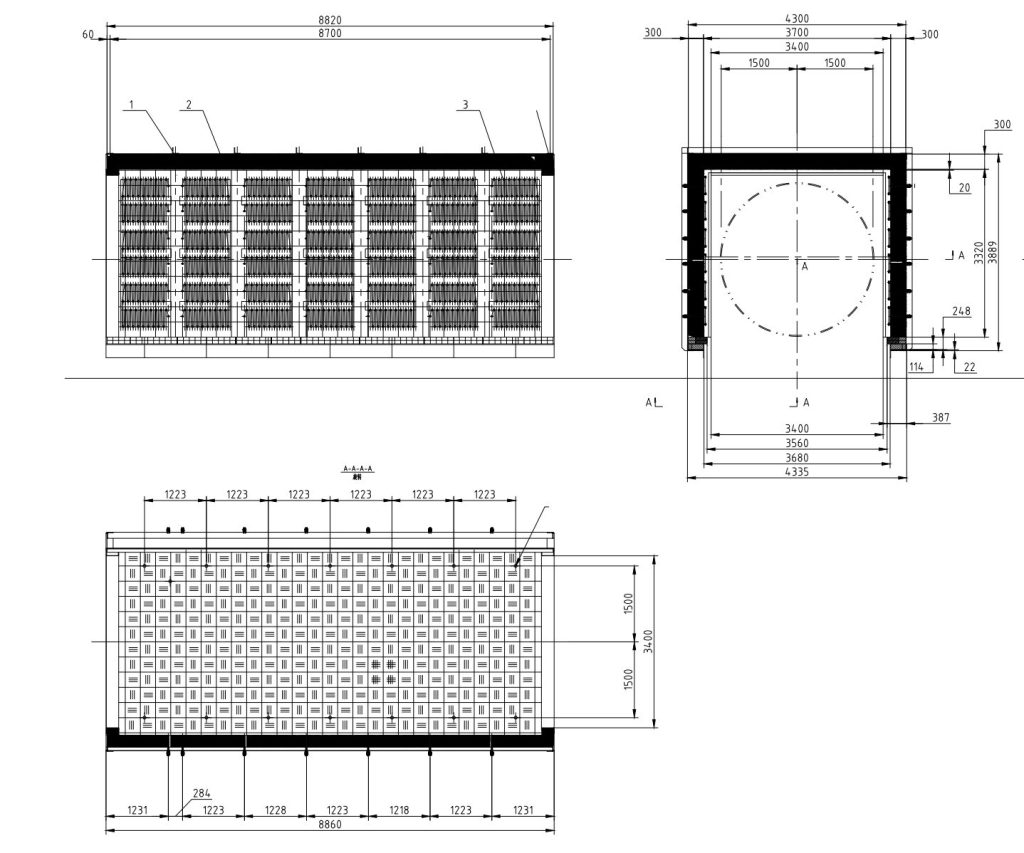

Furnace Lining Structure:

25 mm thick 1260°C standard ceramic fiber backing blanket

300 mm thick 1260°C standard ceramic fiber module

Anchoring System:

Type 304 stainless steel anchors with matching bolts and nuts

Installation tools: professional wrench set for secure fixing, which aids in the maintenance of production furnaces.

This configuration ensures long service life, reliable insulation, and simple maintenance under continuous high-temperature operation of PAN-based carbon fiber production furnaces.

The ceramic fiber module density is only 220 kg/m³, one-fourth that of refractory bricks, significantly reducing furnace shell load and improving heat-up efficiency.

Modules are designed with pre-set welding points. A 1,000-module installation can be completed within 7–10 days, greatly improving construction efficiency, especially for carbon fiber production furnaces.

With low thermal conductivity and low h, ceramic fiber linings provide up to 30% energy compared with traditional refractory materials, thus benefitting PAN-Based Carbon Fiber Production processes.

After installation, the PAN production furnaces show improved performance.

✅ 15–30% higher energy efficiency

HENGRUI’s advanced ceramic fiber lining solution has proven to be an ideal choice for carbon fiber production processes, combining energy efficiency and sustainability in PAN-Based Carbon Fiber Production Furnace settings.