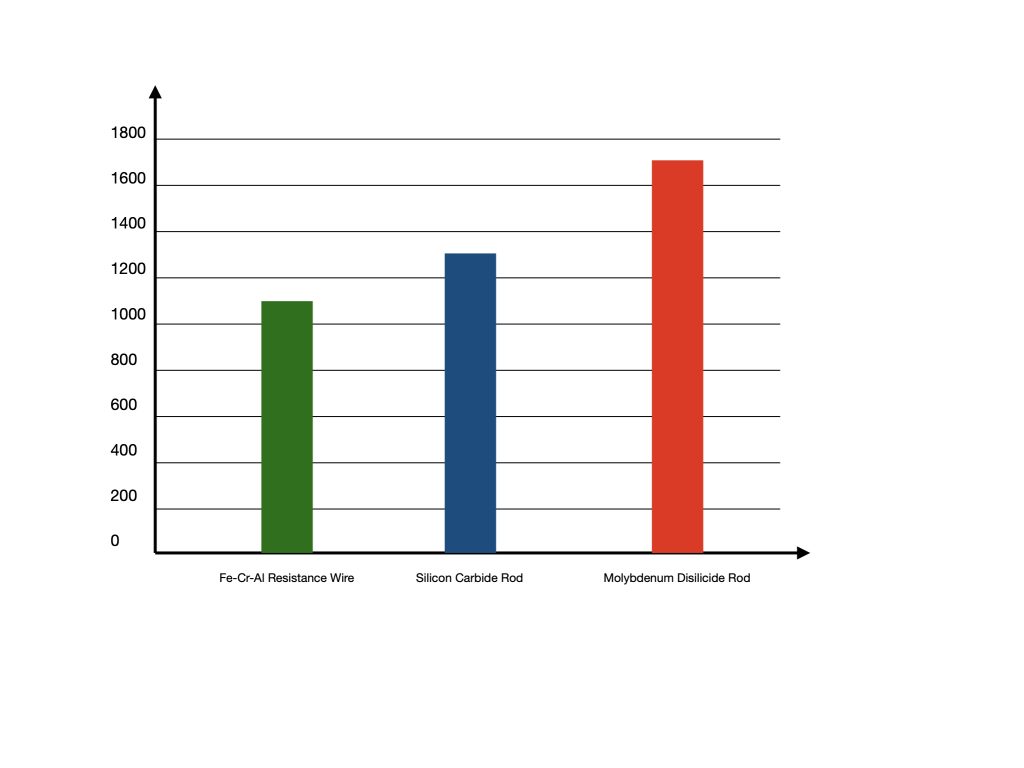

As industrial heating technology evolves, high-performance electric heating elements have become essential for achieving efficient, stable, and energy-saving high-temperature operations. HENGRUI High Temperature Energy-Saving Materials Co., Ltd. offers a comprehensive range of electric heating components, including silicon carbide rods (SiC rods), molybdenum disilicide heating elements (MoSi₂ rods), and resistance wires such as FeCrAl and NiCr alloys.

These products are widely used in muffle furnaces, box furnaces, tube furnaces, and various industrial kilns for ceramics, metallurgy, glass, and refractory materials.

The silicon carbide rod is a non-metallic electric heating element made from high-purity silicon carbide (SiC). The raw materials are molded into rods or tubes, sintered and recrystallized at temperatures around 2000°C.

The SiC rod provides a stable and cost-effective heating solution for mid- to high-temperature industrial applications requiring consistent thermal performance.

The MoSi₂ heating element is a high-temperature electric heater made from molybdenum disilicide, known for its superior oxidation resistance and thermal endurance. Using advanced hot-bending technology, HENGRUI can manufacture MoSi₂ rods in various shapes and configurations.

The MoSi₂ element is ideal for continuous and batch operations requiring ultra-high temperature stability.

FeCrAl heating wire is a cost-effective and durable electric heating material suitable for long-term operation. With maximum service temperatures up to 1400°C, it is commonly used in resistance furnaces operating below 1100°C.

Kanthal APM, Kanthal A-1 (Swedish quality standards)

HRE, 0Cr21Al6Nb (Nb alloyed), 0Cr27Al7Mo2 (Mo alloyed)

Limitations: Lower mechanical strength at high temperatures; tends to deform after long operation due to increased ductility.

NiCr resistance wires, such as Cr20Ni80, are premium electric heating materials known for their excellent high-temperature strength, plasticity, and oxidation resistance.

Although NiCr wires are more expensive than FeCrAl (due to the high cost of nickel), they provide superior stability and longevity, making them ideal for precision heating applications.

✅ Comprehensive Product Range — From SiC and MoSi₂ to FeCrAl and NiCr wires, we offer tailored heating solutions for diverse industries.

🔥 High Temperature Reliability — Products rated for 1100–1800°C ensure consistent performance in demanding environments.

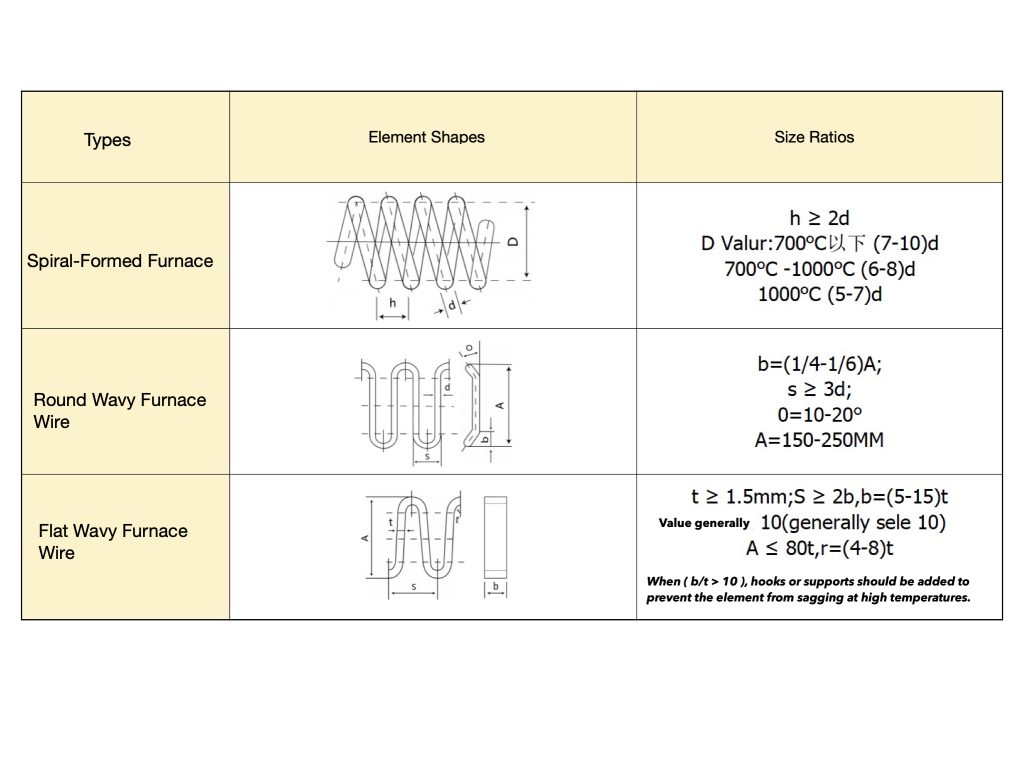

⚙️ Customized Design — Shapes, lengths, and connections are customizable according to furnace requirements.

🌱 Energy Efficient — Optimized heat transfer minimizes power consumption and extends service life.

Ceramics and glass processing

Metallurgy and powder sintering

Refractory material furnaces

Heat treatment and annealing furnaces

Laboratory and industrial muffle furnaces