In the production of optical glass, controlling temperature-uniformity and managing thermal stress are key to ensuring the quality of the final product. Modern annealing furnaces rely on advanced insulation materials to maintain precise thermal profiles. This approach helps minimise defects. One such material is the ceramic fiber board, which is increasingly used as both furnace lining and insulation in optical glass annealing applications.

Optical glass annealing furnaces typically require:

Ceramic fiber boards are well suited because they offer:

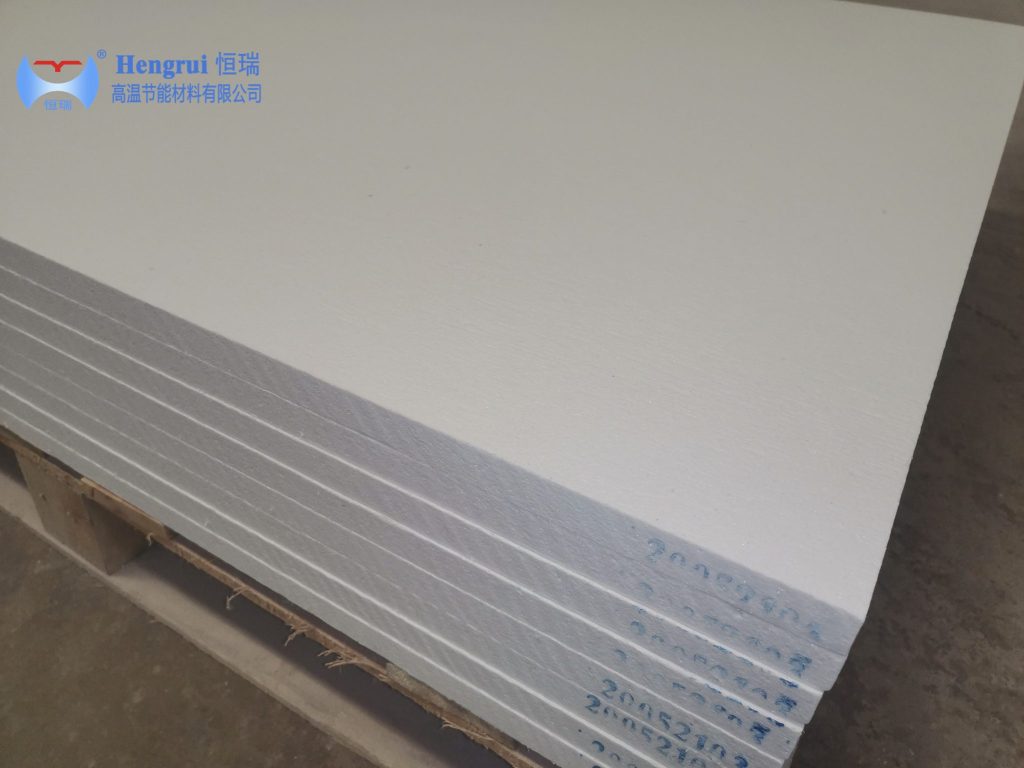

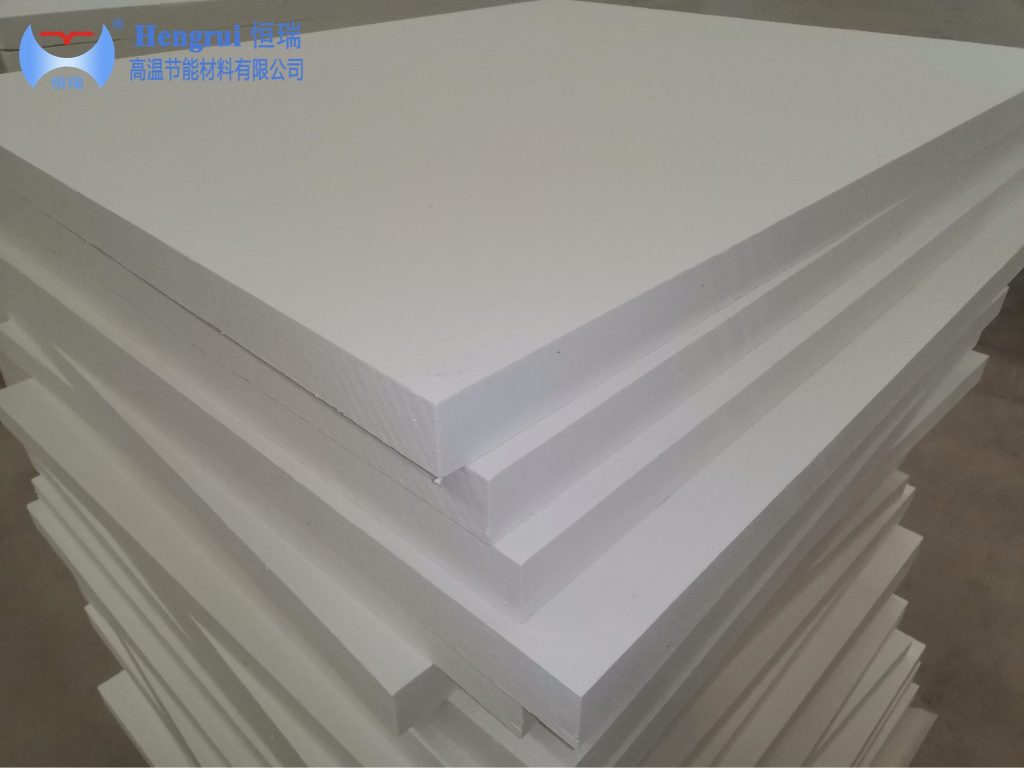

Mechanical stability and dimensional accuracy: Boards are manufactured with uniform thickness and surfaces. This simplifies installation and maintains furnace geometry and insulation integrity.

High-temperature resistance: Many ceramic fiber boards are rated for working temperatures up to and beyond 1260 °C, 1350 °C or more.

Low thermal conductivity and low heat capacity: This means the furnace lining absorbs less heat. It allows quicker temperature changes and tighter control.

Excellent thermal shock resistance: When glass passes through annealing cycles, the insulation must tolerate rapid changes in temperature without cracking or degrading.

When applied inside an optical glass annealing furnace, ceramic fiber boards are used in several ways:

Installation under precision conditions, often requiring boards cut to fit exactly around furnace geometry. This ensures minimal gaps to avoid hot-gas penetration or cold spots.

Furnace wall and roof lining, forming the main insulation barrier to protect the metal shell and maintain internal temperature stability.

Back insulation and secondary lining, supporting the primary hot-face refractory structure.

Thermal barrier for components such as burners or heating elements, ensuring that hot spots don’t introduce local thermal gradients.

Using ceramic fiber boards in the annealing process offers concrete advantages for optical glass production:

Reduced internal stress in glass: By maintaining a stable and uniform annealing environment, the boards help avoid cracking or warping of optical glass parts. This is crucial during rapid or uneven cooling.

Improved dimensional and optical performance: Consistent insulation leads to controlled cooling rates. Consequently, the final product geometry and optical clarity are better.

Energy savings: Lower heat loss through the furnace lining means less energy is required for heating. It also reduces the energy needed for holding at annealing temperatures.

Extended furnace life and reduced maintenance: The mechanical and thermal durability of ceramic fiber boards means less frequent replacement and fewer disruptions.

When specifying ceramic fiber boards for optical glass annealing, typical data to reference include:

Manufacturers of ceramic fiber boards list performance limits, shrinkage under temperature, and mechanical strength values.