In the glass industry, high-temperature operations—from melting to tempering and annealing—demand reliable and efficient insulation materials. Among these, the ceramic fiber blanket stands out as a versatile solution. With its low thermal conductivity, light weight, high temperature resistance and flexibility, it finds broad application in glass melting furnaces, tempering lines and annealing kilns.

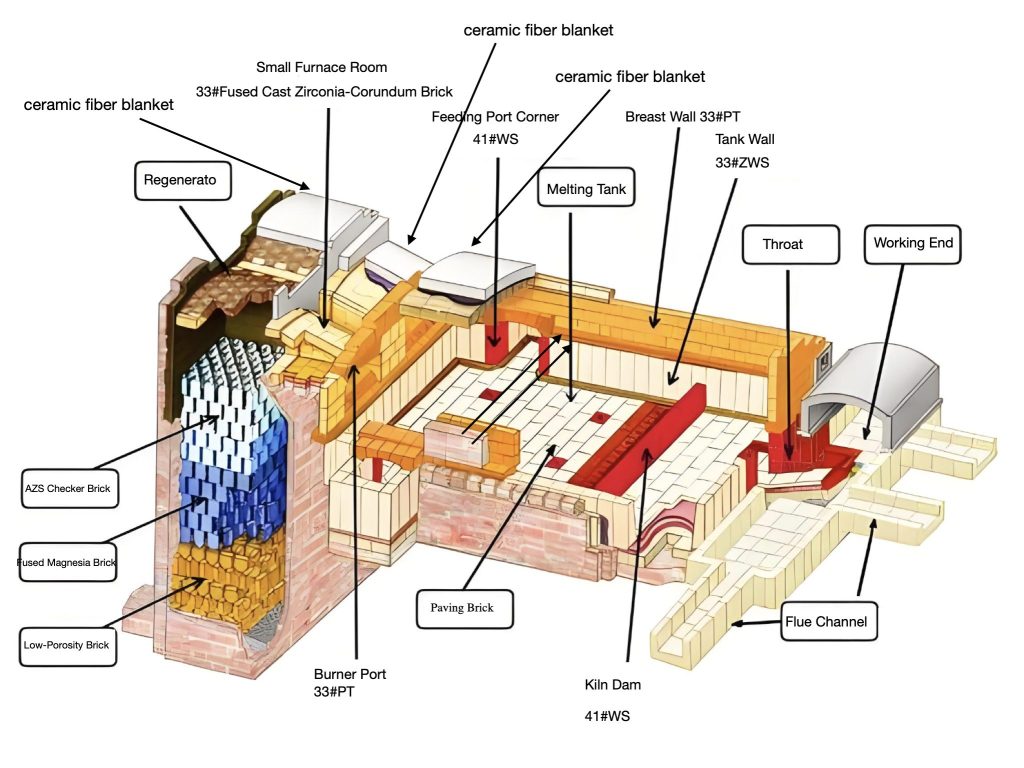

Ceramic fiber blankets are increasingly used for lining glass-furnace structures—such as the melting tank, steel-bath roof, side walls, and annealing furnace walls. They help reduce radiant and convective heat loss, maintain uniform furnace temperatures and lower energy consumption. Thanks to their very low heat capacity and excellent insulation performance, ceramic fiber blankets can shorten heating up time and reduce fuel or electric energy usage significantly compared to older heavy refractories.

In advanced applications, ceramic fiber blanket is paired with ceramic fiber boards or lightweight refractory bricks to form a multi-layer composite insulation system. This modular approach brings easier installation, quicker replacement of damaged sections, and enhanced thermal performance. For glass tempering or annealing lines—where maintenance windows are short—this modular composite design provides practical advantages for uptime and efficiency.

Ceramic fiber blankets are also employed in sealing and protective roles within glass production equipment. For example:

In glass-melting plants, the flue-gas stream or furnace off-gas may pass through heat-recovery or pre-heating units. Ceramic fiber blankets can be used as part of these systems—wrapping ducts, insulation panels or filters—to intercept high temperature particles, protect heat-exchange surfaces and enhance energy recovery. Their high-temperature stability and low heat loss help improve overall plant efficiency.

When specifying ceramic fiber blankets for glass-industry use, key performance criteria include:

Compatibility with aluminum foil or other jacketing when applied to ducts or exhaust systems.

Continuous use temperature (often up to 1260 °C or higher depending on grade).

Thermal conductivity under operating conditions (lower is better).

Density and compressive strength (to ensure durability on furnace surfaces).

Thermal shock resistance and dimensional stability (important for furnace cycles).

The ceramic fiber blanket has established itself as a key insulation material in the glass-industry environment. Whether lining a glass melting furnace, insulating an annealing unit, sealing furnace doors or assisting in heat-recovery systems, it brings a blend of high temperature resilience, energy efficiency, and installation convenience.

As glass manufacturers continue to pursue higher productivity, lower energy costs and better product consistency, the role of ceramic fiber blanket in their insulation strategies will only grow more significant.