Ceramic fiber blanket plays an essential role in optical glass annealing, serving as the primary refractory and thermal-insulation lining in annealing furnaces. Optical glass requires precise and uniform temperature control to prevent internal stress, distortion, or optical defects, and ceramic fiber blanket provides the stable thermal environment needed for these high-precision processes.

Ceramic fiber blanket is widely adopted in optical glass annealing equipment, and HTCC high-temperature atmosphere pusher kilns—due to its comprehensive performance benefits:

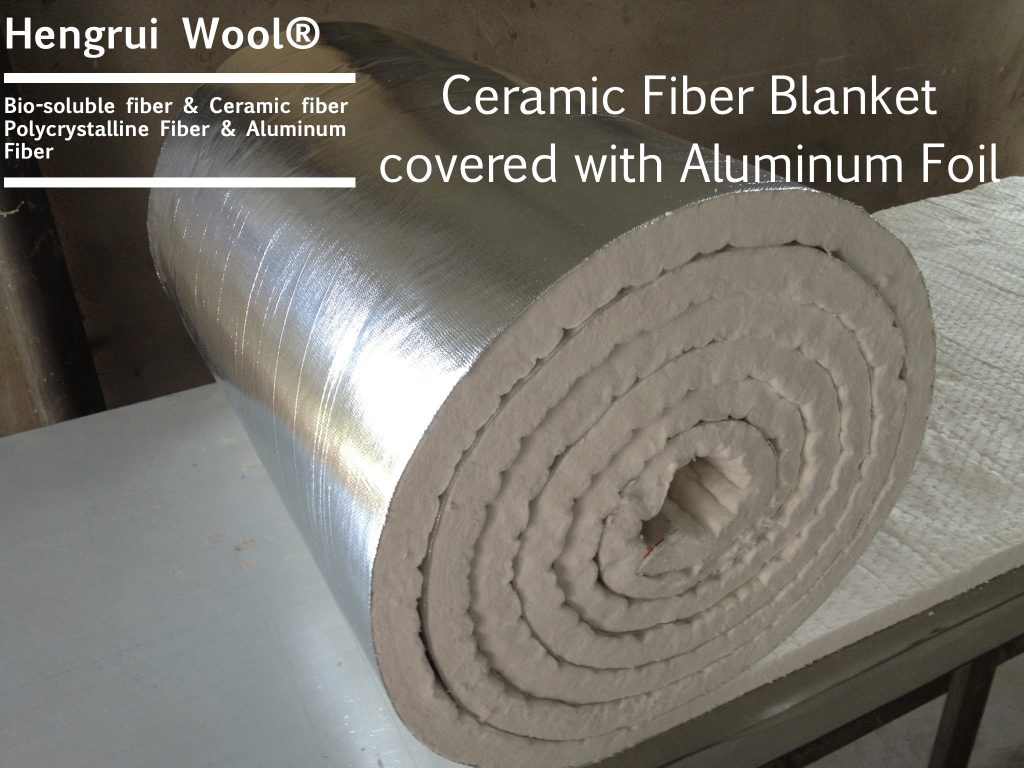

1. Furnace Lining Insulation

Ceramic fiber blanket is commonly applied on furnace walls, top covers, and backing layers. Multiple layers are often installed in combination with fiber boards to form a sealed, energy-efficient insulation system. This helps maintain temperature uniformity (typically within ±2–3 °C), which is crucial for preventing thermal stress in optical glass.

2. Sealing of Furnace Doors and Openings

Its flexibility allows the blanket to be used for sealing furnace doors, peepholes, and structural gaps. This prevents cold air intrusion and stabilizes the annealing curve, ensuring consistent product quality.

3. Thermal Zoning and Partitioning

In annealing furnaces used for optical glass, precise control of cooling zones is critical. Ceramic fiber blanket is used as a thermal barrier between high- and low-temperature zones, helping achieve controlled cooling rates.

Ceramic fiber blanket is a high-performance insulation and sealing material indispensable in optical glass annealing. Its low thermal conductivity, excellent chemical stability, nonflammable characteristics, and resistance to thermal shock help maintain precise temperature control while reducing energy consumption.

Ceramic fiber blankets significantly enhance furnace efficiency, stability, and product quality in modern glass processing.