Wenxian Qilianshan Cement Co., Ltd. successfully applied low thermal conductivity multi-layer composite mullite bricks in the transition zone of its Φ4m×60m rotary kiln. They achieved remarkable energy-saving effects. Initially, these innovative Mullite Bricks were installed in the 18–38m section. After one year of operation, the 18–28m section retained a brick thickness above 140mm. Meanwhile, the 28–38m section remained in good condition. The shell temperature dropped from an average of over 330°C to below 270°C. Encouraged by these results, the company extended their use to the 38–48m section. Upon inspection during annual maintenance, the 28–48m section was still in excellent condition. It maintained a shell temperature below 270°C.

1.High Fuel Consumption:

The cement kiln’s coal consumption was 169.09 kg/t. This was relatively high. The incoming raw coal had a moisture content of 8.57%, ash content of 25.19%, and calorific value of 21,330 kJ/kg.

The 18–59m kiln section used SiC–mullite bricks with a refractory thickness of 200mm. These bricks, while durable, had high thermal conductivity. This caused the kiln shell temperature to exceed 330°C, resulting in significant heat loss, thus making the need for Mullite Bricks evident.

2.Overheating of Support Components:

High shell temperatures also led to elevated bearing temperatures in the second supporting roller assembly.

SiC–mullite bricks are commonly used in non-sintering zones of large and medium-sized rotary kilns. They are known for their excellent wear resistance and thermal shock stability. However, the addition of large amounts of silicon carbide increases their thermal conductivity. This leads to excessive heat transfer and energy loss when compared to the performance of composite Mullite Bricks.

To address these issues, the company replaced the SiC–mullite bricks with low thermal conductivity multi-layer composite mullite bricks.

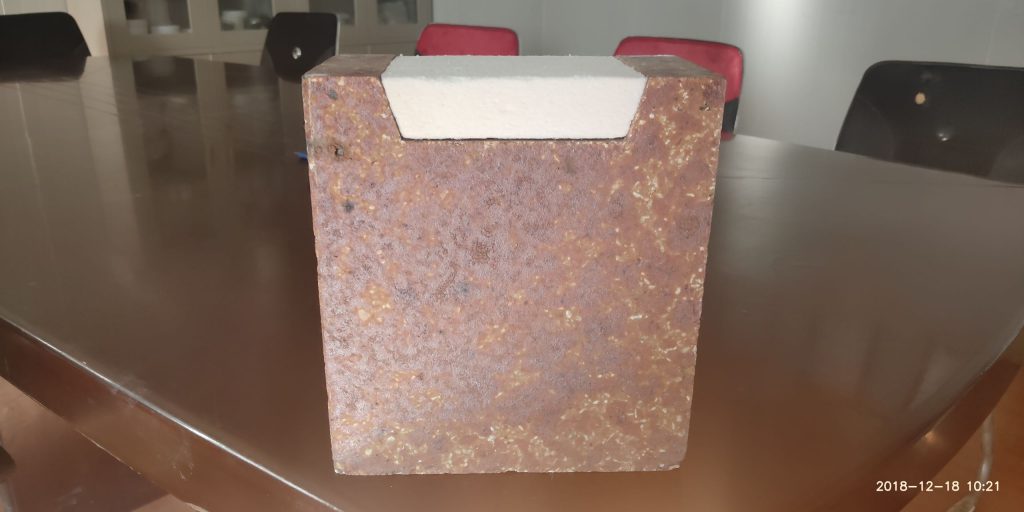

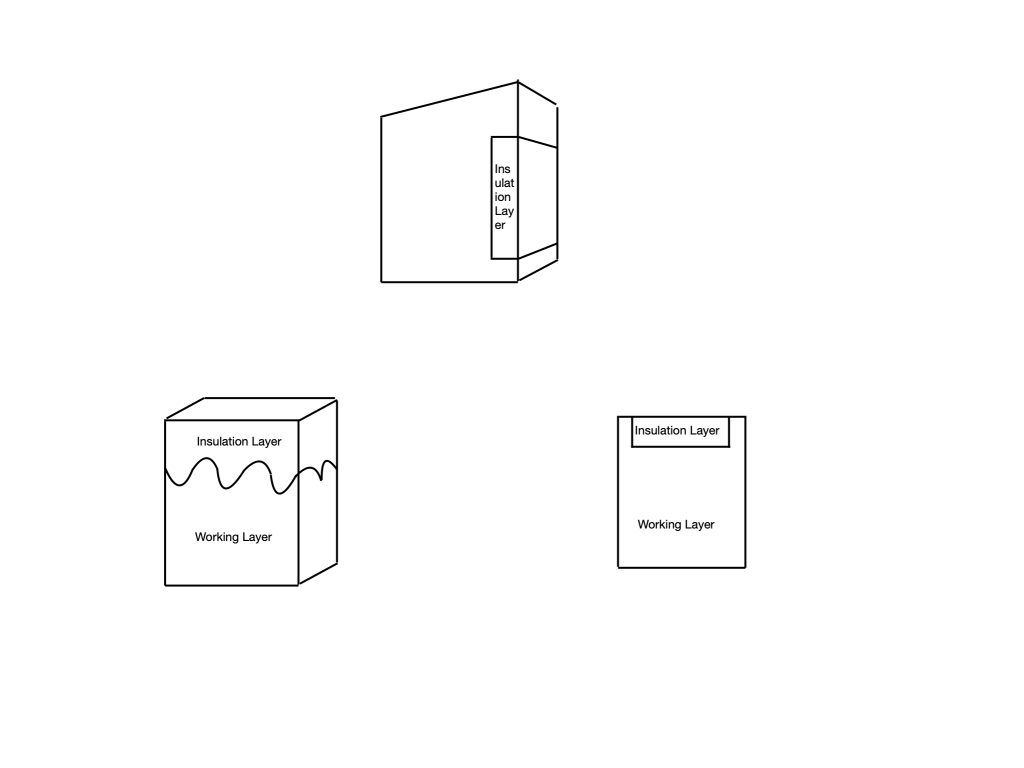

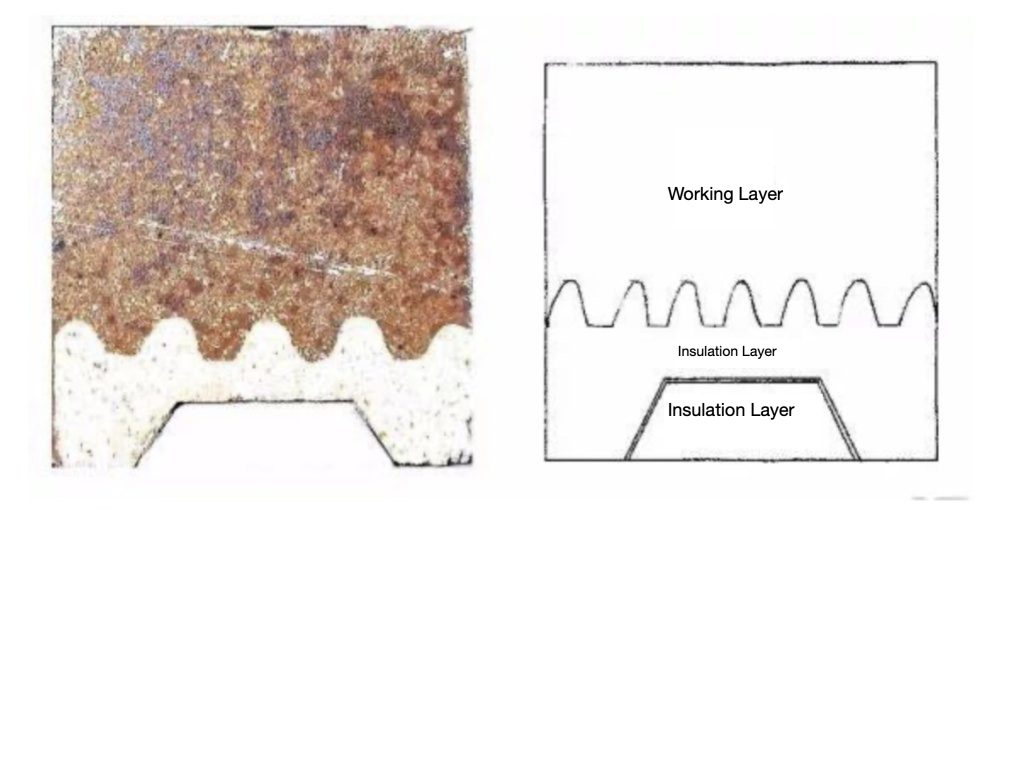

These innovative bricks adopt a three-layer composite structure—a working layer, an insulating layer, and a heat-shielding layer. This structure significantly reduces thermal conductivity, marking a substantial improvement due to the advanced design of Mullite Bricks.

This composite structure gives the brick high strength, excellent wear and corrosion resistance, superior load-bearing capacity under high temperatures, and outstanding thermal shock resistance. It meets the demanding conditions of large-scale cement rotary kilns. Additionally, its low thermal conductivity reduces shell temperature. It decreases fuel consumption and prolongs kiln service life, resulting in significant economic and environmental benefits, which are key advantages of using Mullite Bricks.

After the first installation in 2017 (18–38m section):

In 2018, after extending use to 38–48m:

1.Energy Saving:

Annual coal savings of approximately 1,336 tons.

2.Emission Reduction:

Annual reduction of ~2,700 tons CO₂, 14.2 tons SO₂, and 6 tons NOx.

3.Extended Refractory Service Life:

Even when the remaining brick thickness is 120mm, the shell temperature remains 50–80°C lower than that of standard bricks. This allows for safe continued use and reduces shutdowns for maintenance.

4.Reduced Mechanical Wear:

The lower thermal conductivity and lighter weight reduce stress and wear on the kiln tires and shell. This slows deformation and oxidation, and extends service life of both components.

Although the initial cost of low thermal conductivity multi-layer composite mullite bricks is higher than that of traditional SiC–mullite bricks, their long-term benefits are substantial. They effectively reduce kiln shell and bearing temperatures. They also lower fuel consumption and power usage, cut emissions, extend refractory lifespan, and minimize equipment wear.

Overall, this upgrade significantly reduces operating costs while enhancing both energy efficiency and environmental performance. It is a highly recommended solution for modern cement rotary kilns, especially when considering the advantages of Mullite Bricks.