Refractory Ceramic Fiber

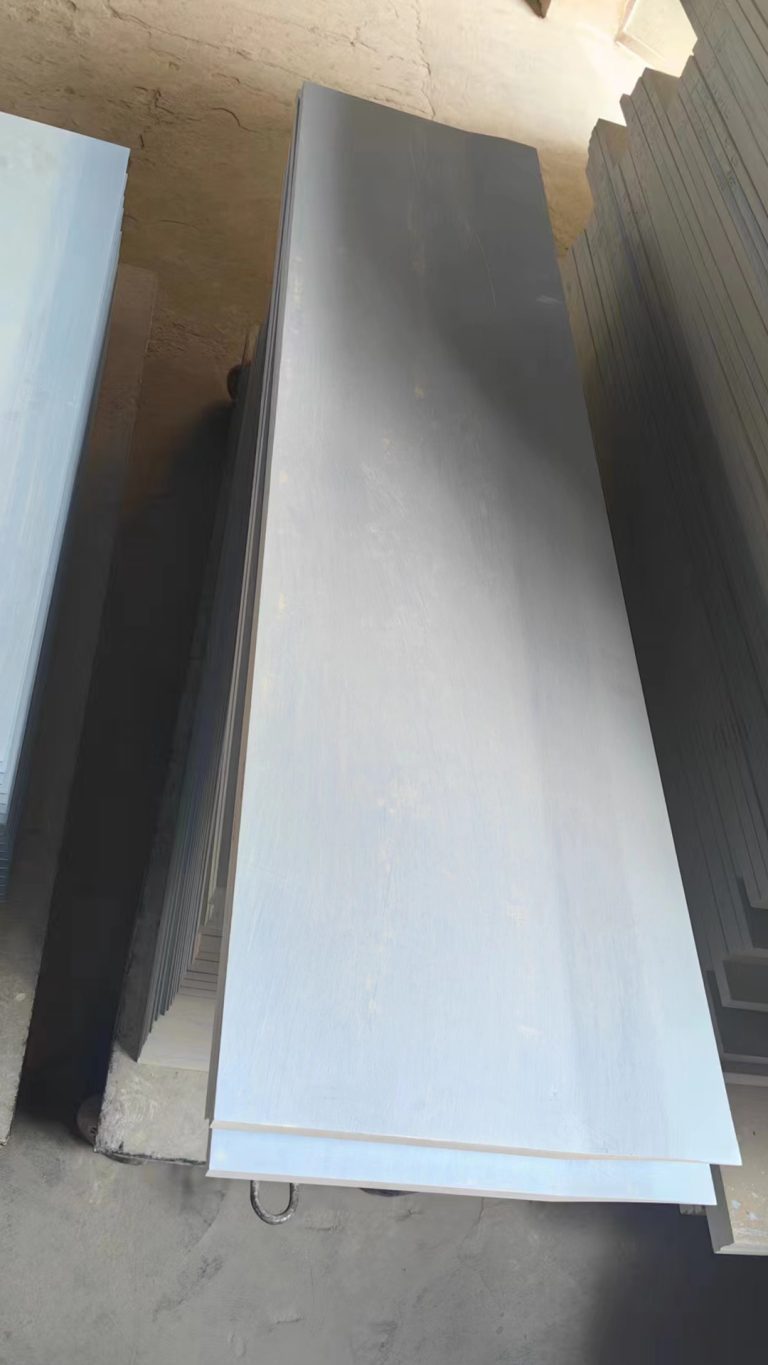

The non-stick aluminum casting tip plate is the key component of the aluminum strip continuous casting and rolling mill, and its quality directly affects the quality of the strip and the yield of production. The casting nozzle material can be divided into various types according to the performance and needs of different casting machines. The non-stick aluminum casting nozzle plate produced by Hengrui is made of ceramic fiber and other materials, which has good elasticity and no deformation. Advantages such as long use time. Its special process can effectively prevent the molten aluminum from corroding the casting nozzle and avoid carbonization; the fracture structure is a fine and uniform layered fiber structure to prevent the existence of flaky flocculent structures; the coating on the working surface is even and smooth to prevent cracks in granular materials And the occurrence of coating peeling phenomenon provides guarantee for high-quality cast plate.

Non-stick aluminum casting nozzle board is a rigid, high temperature resistant ceramic fiber board, which is made of high-purity fiber and adhesive through wet forming process in vacuum environment. Low thermal conductivity, good high temperature stability, gas resistance

Flow scour, uniform density, excellent resistance to thermal shock and chemical corrosion (except phosphoric acid, hydrofluoric acid, concentrated alkali) and easy installation. It helps to reduce energy bills and cycle times due to its high insulating capacity, and protects the furnace shell from thermal shock. It can be directly used as refractory surface material.

Due to technological requirements, a small amount of organic or inorganic binder is added in the production process. If an organic binder is added, the organic binder will burn out at temperatures between 285°C and 450°C when first heated by the end user. After the organic binder has burned out, the color of the board is white.

| Project | Model | Density (KG/M3) | Modulus of fracture (816℃·Mpa) | Thermal expansion coefficient(680℃·K-1) | Thermal conductivity (540℃w/m`k) | Max operating temperature(℃) |

| Non-stick aluminum cast nozzle board | HR-NS | 450-500 | 42-48.8 | 1.35-1.56*10-6 | 0.12-0.15 | 1260 |

Aluminum sheet and foil casting and rolling industry.