What Are Ceramic Fiber Shaped Products?

01. Product Description

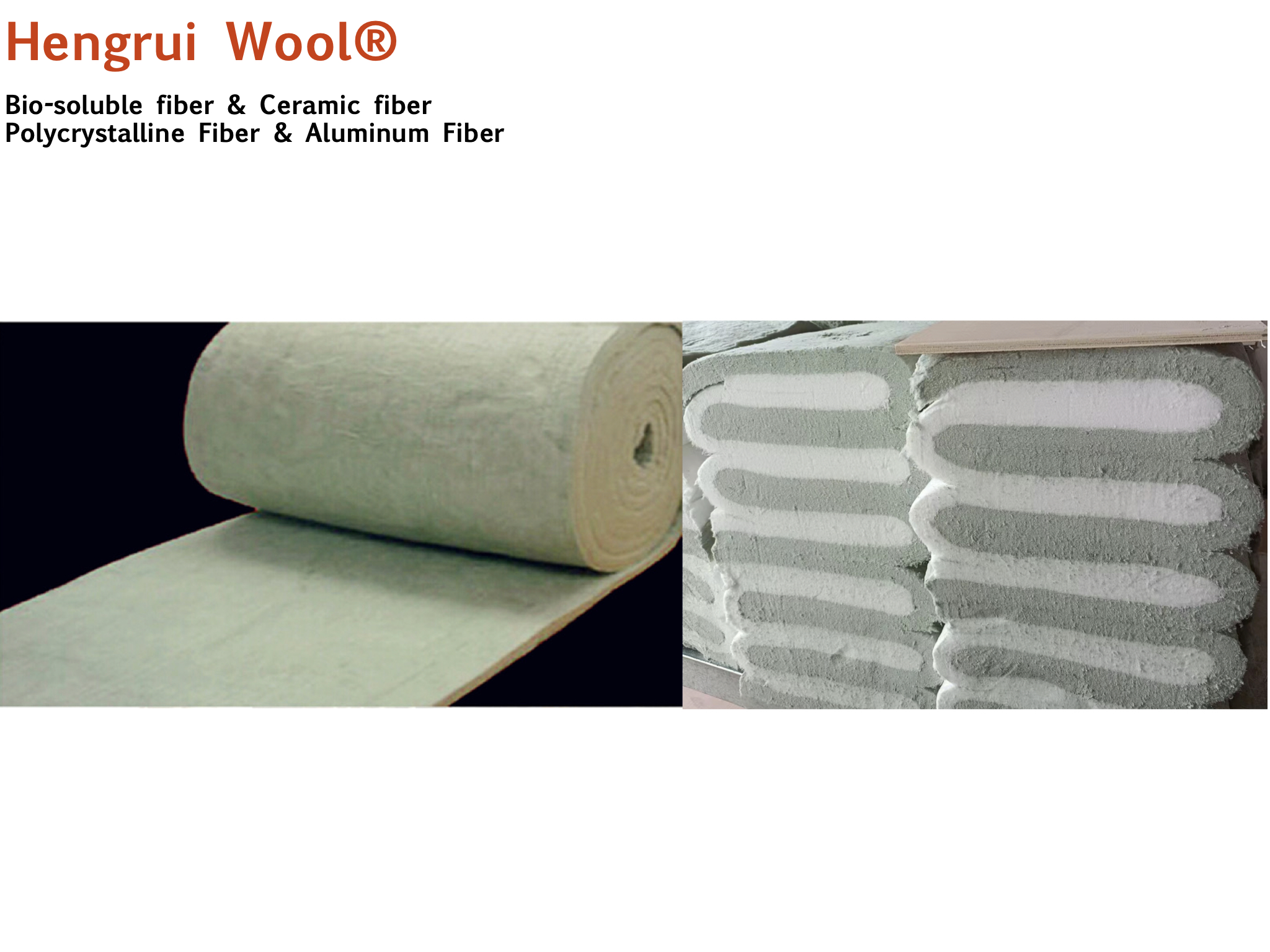

The HengRui 1500℃ chromium-containing ceramic fiber blanket is a light green, flexible, interwoven fiber blanket that integrates refractory, insulation, and thermal protection functions. It features long fibers with uniform diameter, low shot content, and can be rolled. Packaged in woven bags, 2 rolls per bag.

Performance

- High temperature resistance (suitable for long-term use in kilns up to 1350℃)

- Low thermal conductivity (<0.186 W/m·K at 1000℃)

- Lightweight (128 kg/m³)

- Stable performance (linear shrinkage < -3% at 1350℃)

- Excellent thermal shock resistance and tensile strength

- Provides insulation, heat resistance, fire protection, sound absorption, and noise reduction

Manufacturing Process

- Produced by high-temperature melting and fiberizing through the spinning method, followed by double-sided needling. Free from additives, the fibers are highly interwoven, giving the blanket higher delamination resistance, wind erosion resistance, flexibility, and tensile strength compared to standard fiber blankets. This improves performance in practical applications and reduces material loss.

Typical Applications

- Industrial construction material kilns and heating devices

- High-temperature pipeline linings

- Power boilers, gas turbines, and nuclear insulation systems

- Chemical industry high-temperature reactors and heating equipment linings

- Fireproofing and insulation in high-rise buildings

- Kiln doors, covers, and high-temperature filtration materials.

Difference Between 1500℃ Chromium Fiber Blanket and 1400℃ Zirconium Fiber Blanket

Compared with zirconium-containing blankets, the chromium fiber blanket replaces zirconia components with chromia (Cr₂O₃). As a result, its temperature resistance and continuous service temperature are both 100℃ higher. The chromium fiber blanket withstands up to 1500℃, with a continuous working temperature of 1350℃.

Other Chromium Fiber Products

HengRui chromium-containing ceramic fiber blankets can be further processed into modules, boards, textiles, and other finished products.