Overview

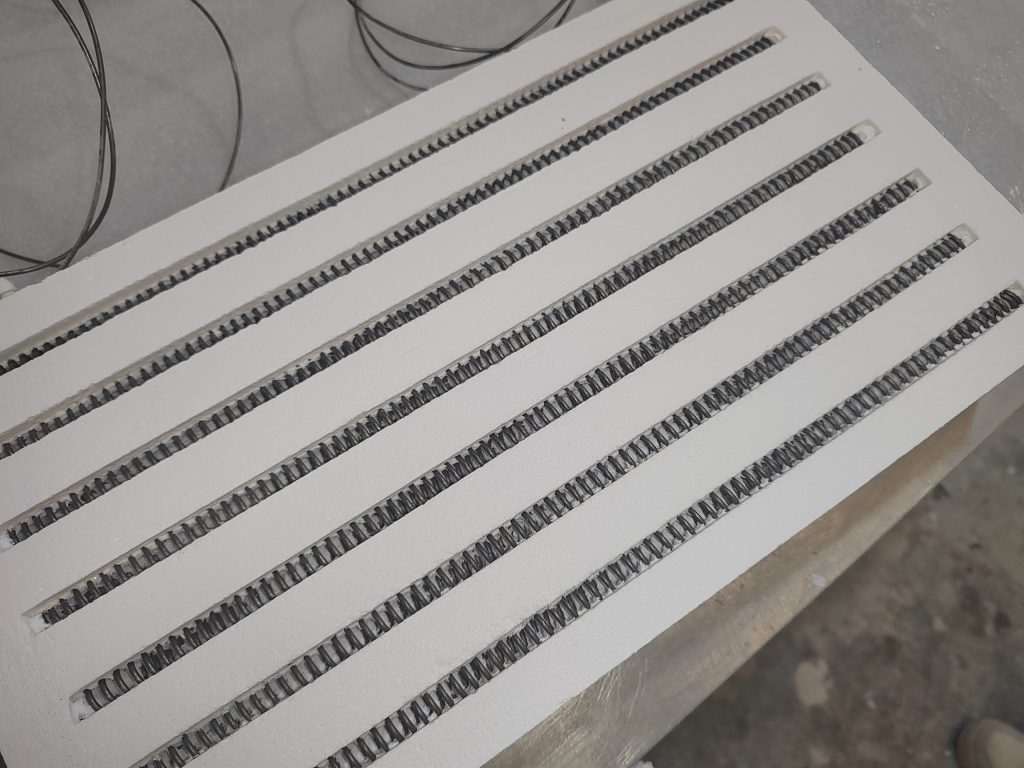

In industrial furnaces, muffle furnaces, and electric heaters, metal tubular heating elements rely on high-performance resistance wire to generate stable and efficient heat.

The most commonly used materials are Fe-Cr-Al (Iron-Chromium-Aluminum) and Ni-Cr (Nickel-Chromium) alloys.

Choosing between these two directly impacts temperature capability, lifespan, oxidation resistance, and cost efficiency.

This article compares the two alloys and summarizes their design advantages for high-temperature electric heating applications.

1.Working Principle

Resistance heating utilizes the Joule heating effect — when electric current passes through a conductor, heat is generated.

The heating performance is determined by material resistivity (ρ), surface load (W/cm²), and structural design.

Proper alloy selection ensures high energy efficiency and long-term reliability.

2.Comparison: Fe-Cr-Al vs Ni-Cr Alloys

Specially designed for ceramic fiber modules, this type features an L-shaped steel base for firm attachment to the furnace wall. It provides excellent stability for folded and stacked modules, which is essential for systems like Ceramic Fiber Module/Z-Block.

| Property / Feature | Fe-Cr-Al Alloy | Ni-Cr Alloy |

| Max Operating Temperature | Up to 1400°C | Up to 1200°C |

| Service Life | 2–4× longer than Ni-Cr | Shorter lifespan |

| Surface Load Capacity | High — allows faster heating and material savings | Moderate |

| Oxidation Resistance | Excellent — forms dense Al₂O₃ protective film | Good — forms Cr₂O₃ film |

| Density | Lower (lightweight) | Higher |

| Electrical Resistivity | High — supports thicker wire, longer life | Moderate |

| Sulfur Resistance | Excellent — resistant to sulfur corrosion | Poor — easily corroded in sulfur atmospheres |

| High-Temperature Strength | Lower — may deform under prolonged high heat | High — maintains shape and strength |

| Plasticity After Use | Becomes brittle after long-term use | Retains ductility after cooling |

| Emissivity | Slightly lower | Higher emissivity after oxidation |

| Magnetic Properties | Non-magnetic only above 600°C | Non-magnetic at all temperatures |

| Corrosion Resistance | Good, especially in sulfur environments | Better in neutral or non-sulfur atmospheres |

| Cost | Low — nickel-free and economical | Higher — due to nickel content |

3.Key Takeaways

🔹 Fe-Cr-Al Alloy Advantages

- Higher operating temperature (up to 1400°C)

- Longer lifespan and higher surface load

- Excellent oxidation and sulfur resistance

- Lower density and material cost

- High resistivity for efficient design

🔹 Ni-Cr Alloy Advantages

- Stronger mechanical integrity at high temperature

- Retains flexibility after long-term use

- Higher emissivity for faster radiant heating

- Non-magnetic and stable performance

- Better corrosion resistance in neutral environments

4.Application Recommendations

| Application Scenario | Recommended Alloy | Reason |

|---|---|---|

| High-temperature furnaces (≥1300°C) | Fe-Cr-Al | Superior oxidation resistance and temperature endurance |

| Long continuous operation | Fe-Cr-Al | Extended lifespan, low maintenance |

| Applications requiring high strength & flexibility | Ni-Cr | High tensile strength and ductility |

| Corrosive or sulfur-rich atmosphere | Fe-Cr-Al | Excellent sulfur resistance |

| Precision lab or magnetic-sensitive instruments | Ni-Cr | Non-magnetic and stable behavior |

5.Conclusion

Both Fe-Cr-Al and Ni-Cr alloys are reliable materials for electric heating elements, each excelling in specific operating environments.

- Fe-Cr-Al is ideal for high-temperature, cost-sensitive, and oxidation-critical applications.

- Ni-Cr is preferred for mechanically demanding or magnetic-sensitive systems requiring durability and flexibility.

By understanding these alloy characteristics and matching them with the right furnace design, engineers can ensure high efficiency, long service life, and stable heating performance.