The heat resistance and heat preservation mechanism of aluminum silicate refractory fiber.

like other refractory materials is determined by its own chemical and physical properties. Aluminum silicate refractory fiber has white color, loose structure, soft texture. Its appearance is like cotton wool which is an important condition for its good heat insulation and heat preservation performance.

The thermal conductivity of aluminum silicate refractory fiber is only one third of that of refractory concrete under 1150℃

So the heat conduction through it is very small. Its weight is only about one-fifteenth of ordinary refractory bricks and its heat capacity is small .

The aluminum silicate refractory fiber is white and soft, and has a high reflectivity to heat. Most of the heat radiated to the refractory fiber is reflected back.

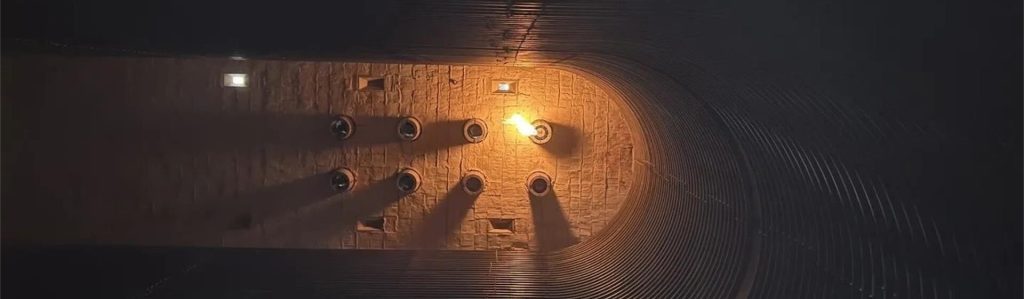

when the refractory fiber is used as the lining of the heat treatment furnace . The heat in the furnace are concentrated on the heated workpiece after several times reflection. It can withstand sudden changes in cold and heat without cracking. Has a good insulation and noise reduction properties, and its chemical stability is also very good.

From a thermal point of view, aluminum silicate refractory fiber also has good high temperature performance. Because the main mineral composition of kaolin used to make refractory fibers is kaolinite (Al2O3·2SiO2·2H2O). The refractoriness of kaolin is generally higher than that of clay .

its refractory temperature is closely related to its chemical composition.