What Is Vitreous Ceramic Fiber?

Vitreous ceramic fiber is a high-performance refractory material widely used in industrial furnaces, kilns, boilers, and thermal equipment. Known for its excellent thermal insulation, lightweight structure, and durability, vitreous ceramic fiber is a crucial material for industries requiring reliable high-temperature insulation solutions.

Raw Materials and Composition

The manufacturing of vitreous ceramic fiber starts with a precise blend of alumina (Al₂O₃) and silica (SiO₂) as the primary raw materials. Depending on the grade, zirconia (ZrO₂) may also be added to enhance thermal stability and service temperature.

1,430°C Grade: Contains a higher content of alumina, silica, and zirconia for superior resistance to extreme heat.

1,260°C Grade: Made from high-purity alumina and silica, sometimes using kaolin clay.

The Fiber-Forming Process

1. High Temperature Resistance

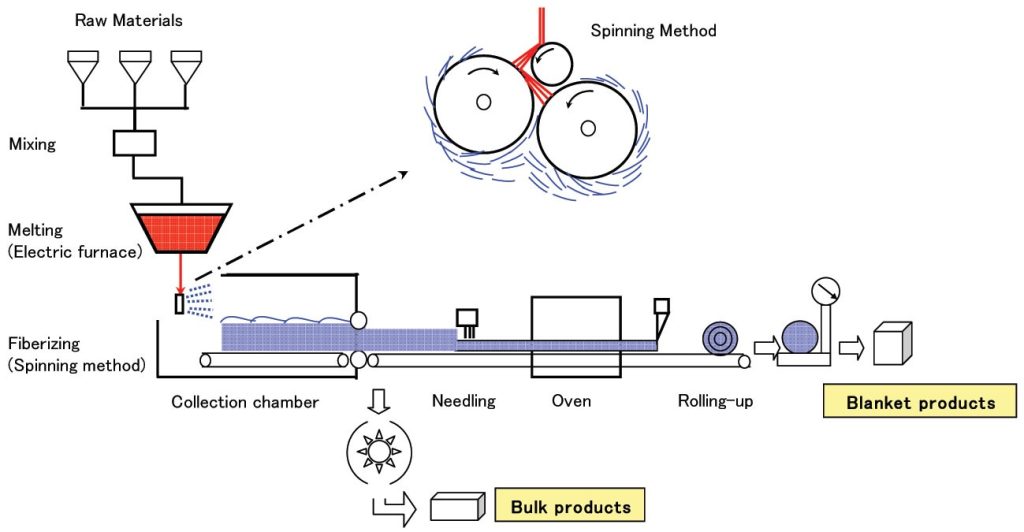

- 1. High-Temperature Melting

- The raw materials are melted at approximately 2,000°C in a high-efficiency furnace, creating a uniform molten mixture.

2.Fiber Formation Methods

- There are two main methods to form ceramic fibers:

- Spinning Method: The molten mixture is ejected through a nozzle onto high-speed rotors. Centrifugal force stretches the molten droplets into long fibers, producing bulk ceramic fiber material.

- Blowing Method: Compressed air or steam is used to blow the molten mixture into fibers, resulting in a fine, fluffy bulk fiber.

3.Needling and Lubrication

- The bulk fibers are lubricated and mechanically needled to increase structural integrity. This step ensures the fibers are interlocked, giving the material strength and flexibility.

4.Heat Treatment

- The lubricant is removed through controlled heating, leaving behind a finished ceramic fiber blanket or other fiber-based products.

Characteristics of Vitreous Ceramic Fiber

- High service temperature (up to 1,430°C depending on grade)

- Low thermal conductivity, providing superior insulation

- Lightweight yet strong, reducing furnace load

- Excellent thermal shock resistance, suitable for rapid heating and cooling cycles

- Chemical stability, resistant to most corrosive environments

Applications of Vitreous Ceramic Fiber

- Vitreous ceramic fibers are widely used in:

- Industrial furnace linings

- Kiln insulation and seals

- Boiler and heater insulation

- Petrochemical and metallurgical equipment

- Fire protection and thermal barriers

- These properties make vitreous ceramic fiber an essential material for industries seeking energy efficiency and long-term reliability in high-temperature environments.

Conclusion

The manufacturing process of vitreous ceramic fiber—from raw material selection to high-temperature melting, spinning or blowing, and final heat treatment—ensures the production of lightweight, durable, and efficient insulation materials. With service temperatures up to 1,430°C, vitreous ceramic fiber has become a trusted solution in modern industrial insulation.

👉 Contact Hengrui High Temperature Company today to learn more about our vitreous ceramic fiber products and customized insulation solutions.