Ceramic fiber modules—also known in some applications as Z-BLOK insulation units—are manufactured from needled ceramic fiber blankets, compressed and shaped on specialized equipment to precise dimensions. During production, each module retains a specific amount of compression. Once installed inside the furnace lining, these components expand in the same direction, pressing tightly against each other to form a seamless, highly efficient insulation system.

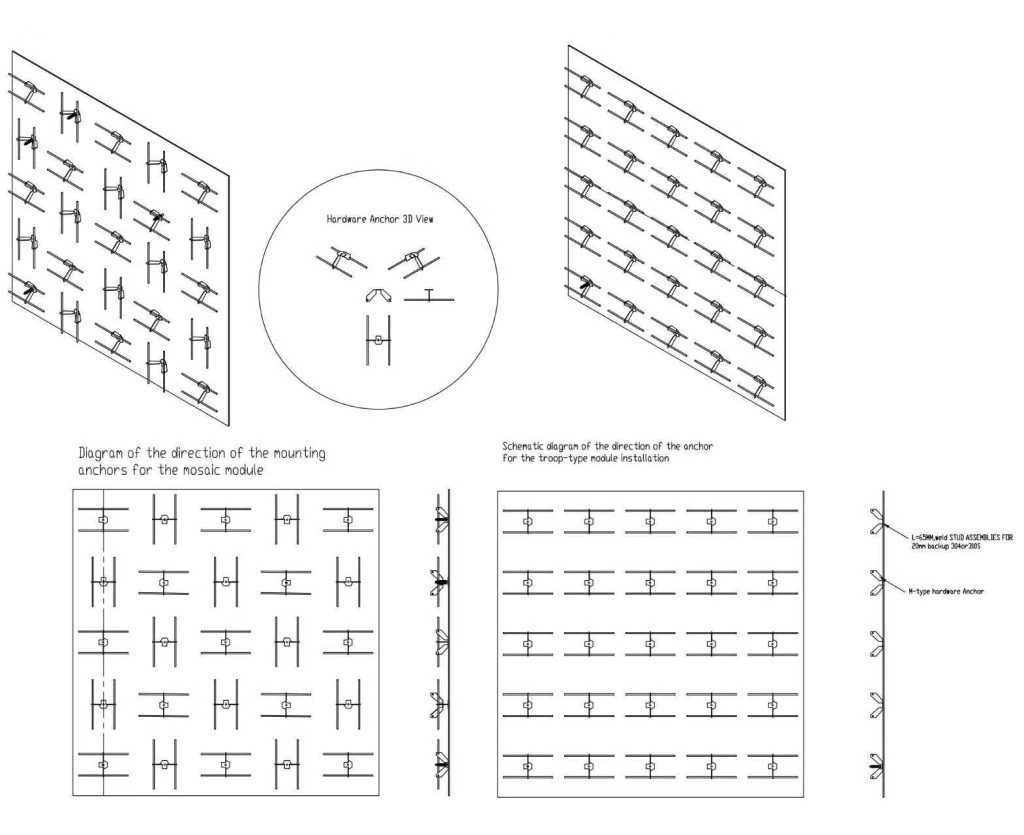

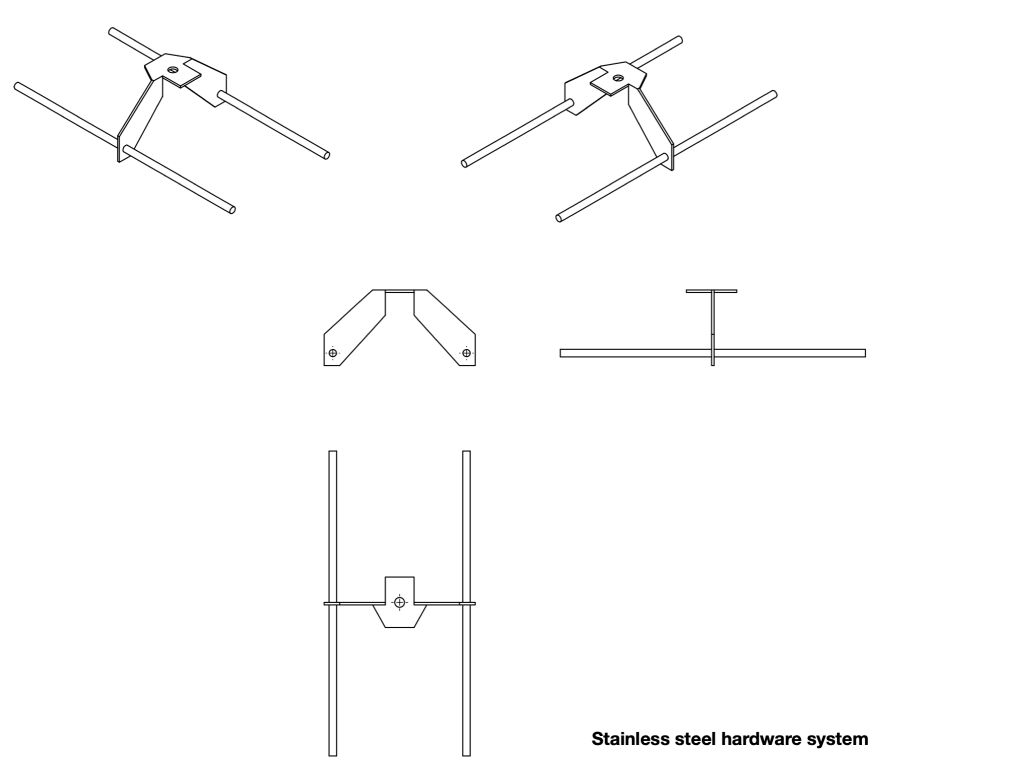

Both ceramic fiber modules and Z-BLOK units can be secured directly onto the furnace steel shell using various types of anchoring hardware.

Preparation Before Installing Ceramic Fiber Modules / Z-BLOK Units

Proper preparation is essential to ensure secure anchoring and a high-quality furnace lining.

1.1 Surface Cleaning

Before installation, remove rust and oxide layers from the furnace wall steel plates. A clean metal surface ensures strong welding performance when attaching studs or anchors.

1.2 Marking and Layout

According to the design drawings, mark the exact layout for the ceramic fiber modules or Z-BLOK units on the furnace wall.

Also mark the exact positions of the anchor welding points or studs.

1.3 Welding the Anchor Studs

Based on the design specifications, weld the correct-length studs onto the furnace steel shell.

During welding:

- Protect the stud threads from welding slag

- Ensure welding sparks do not touch the threaded areas

- Make sure all studs are firmly welded and properly aligned

This ensures stable installation for both ceramic fiber modules and Z-BLOK blocks.

1.4 Installing the Backup Blanket

Before installing the insulation units, lay a layer of ceramic fiber blanket on the furnace wall, followed by a second offset layer.

Key requirements:

- Offset the joints of the two layers by at least 100 mm

- Use temporary clamps for easier positioning, especially on the roof section

This base layer strengthens insulation performance and reduces heat loss.

Step-by-Step Installation Procedure

(for Ceramic Fiber Modules and Z-BLOK Units)

Step 1: Fix the Guide Sleeve

Attach the guide sleeve onto the welded anchor stud. This sleeve helps guide the module into correct alignment.

Step 2: Position the Module / Z-BLOK Unit

Align the center tube of the ceramic fiber module—or Z-BLOK block—with the guide sleeve.

Press it firmly and vertically so that the unit sits flush against the furnace wall.

Step 3: Tighten the Nut

Using the special socket tool, move the nut through the guide sleeve and tighten it securely on the stud. This fixes the module in place.

Step 4: Remove the Center Plastic Tube

After the unit is fixed, pull out the center plastic tube.

Step 5: Fill the Center Void

Fill the central cavity with ceramic fiber blanket to eliminate gaps and ensure insulation continuity.

Step 6: Cut the Binding Straps

Remove the straps that kept the Z-BLOK or ceramic fiber module compressed during transport.

The insulation unit will expand and tightly interlock with surrounding blocks.

Step 7: Flatten and Compress the Compensation Blanket

Press down the compensation blanket to ensure a uniform surface and tight coverage over joints.

Step 8: Install the Next Row

Continue installing modules row by row, repeating the same procedure until the entire furnace lining is complete.

Conclusion

Whether using standard ceramic fiber modules or Z-BLOK insulation units, proper preparation and installation techniques are critical.

When installed correctly, these high-temperature insulation components expand to form a dense, gap-free thermal barrier, resulting in:

- Reduced heat loss

- Improved furnace energy efficiency

- Extended service life of furnace equipment

- Stable and safe operation under high temperatures