Introduction: Why Ceramic Fiber Matters in RTO

In the field of waste gas treatment, Regenerative Thermal Oxidizers (RTOs) play a vital role in reducing volatile organic compounds (VOCs) and methane emissions. To achieve high efficiency and stable operation, the choice of insulation material is crucial. Ceramic fiber lining has become the preferred solution thanks to its lightweight, excellent thermal performance, and durability.

Key Advantages of Ceramic Fiber Lining in RTO

1. Superior Energy Efficiency

Ceramic fiber linings feature low heat storage and a thermal conductivity as low as 0.035 W/(m·K). This ensures faster heating and cooling cycles while minimizing heat loss, saving fuel during VOC treatment.

2. Space-Saving Design

Compared with traditional refractory insulation, ceramic fiber linings are thinner yet more efficient. This not only saves installation space but also increases the volume of the regenerator chamber, improving system efficiency.

3. Outstanding Thermal Shock Resistance

RTO systems often undergo frequent temperature fluctuations due to airflow switching. Ceramic fiber’s excellent thermal shock resistance prevents cracking, ensuring long-term stability and reduced maintenance.

4. Strong Chemical Stability

Made from inorganic non-metallic materials, ceramic fibers exhibit high resistance to harsh gases and oil contamination, prolonging the service life of the furnace lining.

5. Reliable Sealing Performance

Pre-compressed refractory fiber modules expand after installation, forming a tight and seamless insulation layer without the need for expansion joints, guaranteeing operational safety.

RTO Technologies and Efficiency Improvements

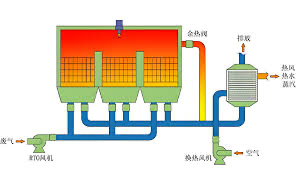

Two-Chamber RTO

- Simple and cost-effective, but VOC destruction efficiency is limited to 95%.

- Heat recovery efficiency: ~90%.

- Annual carbon reduction benefits are significantly lower compared with advanced systems.

Three-Chamber RTO

- Adds a purge function, increasing VOC destruction rate to 99%+.

- Generates much higher carbon reduction revenues, making it suitable where environmental regulations are strict.

- However, large-volume three-chamber RTOs may suffer from uneven flow distribution and higher operational costs.

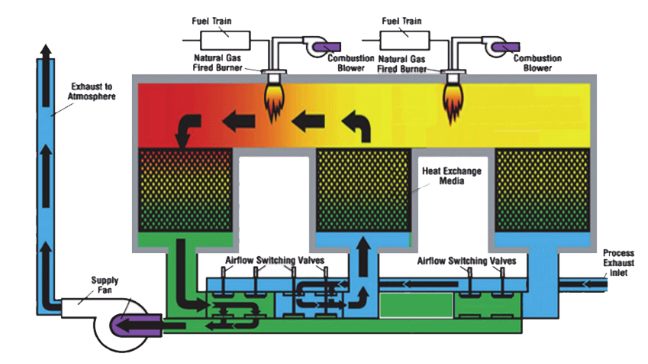

Rotary Valve RTO – The Industry Benchmark

- Uses a rotary gas distribution valve instead of reciprocating valves.

- Provides continuous, low-impact airflow switching, improving sealing and extending valve lifespan.

- Achieves 95%+ heat efficiency and outlet gas temperature as low as 40°C, minimizing energy loss.

- Now the mainstream choice for coal mine methane oxidation and VOC treatment projects, especially under the CCER carbon reduction policy.

Why Choose Ceramic Fiber for RTO Insulation?

When integrated into RTO systems, ceramic fiber linings enhance efficiency by:

- Reducing fuel consumption.

- Supporting higher destruction efficiency of VOCs and methane.

- Extending equipment lifespan with stable insulation performance.

- Contributing to carbon reduction revenues under environmental policies.

Conclusion

With the global push toward sustainable development and carbon neutrality, combining ceramic fiber furnace linings with advanced RTO technologies (especially rotary valve RTOs) provides the most efficient, durable, and eco-friendly solution for industrial exhaust gas treatment.

👉 Contact Hengrui High-Temperature Materials for customized ceramic fiber insulation solutions tailored to your RTO system.