Hengrui H-temperature Casting Tips and Nozzles excel in high-temperature applications, The proper installation and precise adjustment of continuous casting tips and nozzles play a crucial role in the aluminum sheet casting and rolling process, directly impacting the surface quality of the cast-rolled strips. As a core component in cast-rolling production, the cast-rolling nozzle (particularly the feeding nozzle) optimizes internal fluid dynamics by equalizing the metal flow velocity across the nozzle outlet cross-section while maintaining temperature uniformity. This enhancement significantly improves the final surface quality of cast-rolled sheets.

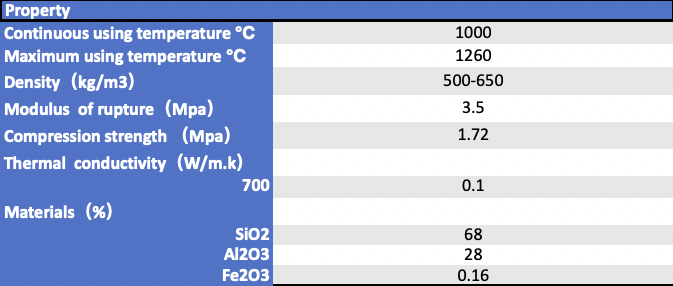

TECHNICAL DATA OF Ceramic Fiber Continuous Casting Tips and Nozzles

*Classification temperature of the fibers used

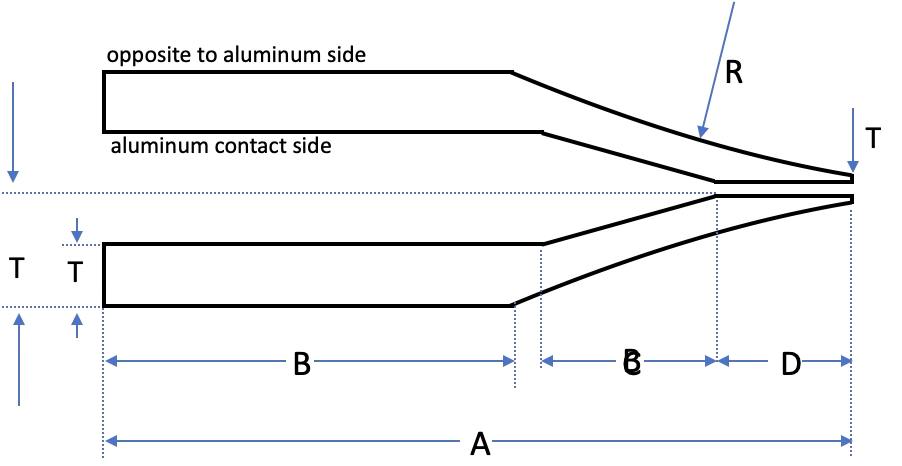

Using the example diagram

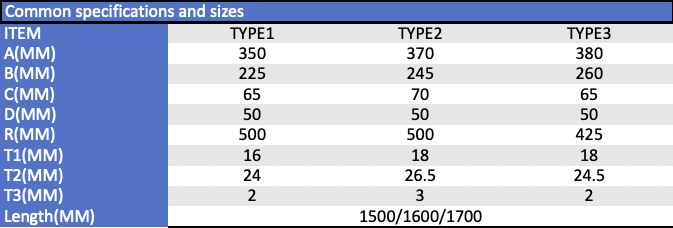

Size

Export Wooden Crate Packaging Solution

1. Material Compliance

- Use kiln-dried plywood (ISPM-15 certified) to meet international phytosanitary standards.

- No chemical treatment required for customs clearance.

2. Customized Dimensional Planning

- Measure product dimensions (L×W×H) with 5cm clearance allowance.

- Reinforce corners with 2cm thick wooden battens for structural integrity.

3. Protective Cushioning

- Line interior with 3cm high-density EPS foam boards (blue anti-static variant recommended).

- Implement double-layer foam for fragile components (minimum 5cm thickness).

4. Secure Assembly

- Use stainless steel corner brackets and waterproof strapping (≥25mm width).

- Apply "Fragile" and "This Side Up" labels in compliance with ISO 780 standards.

5. Quality Control

- Conduct 1.2m drop test before shipment.

- Provide moisture-proof PE lining for humid climates.

HENGRUI H-TEMPERATURE ENERGY-SAVING MATERIALS CO.,LTD

Zheshang Industrial Park. Xiping county. Zhumadian City, China.

TELL:0396-6278666 mail: [email protected] www.ceramicfiberfactory.com