In the world of industrial insulation, one size rarely fits all. While standard ceramic fiber blankets and boards are essential, many thermal management challenges involve complex geometries, tight spaces, and specific airflow requirements. This is where Ceramic Fiber Vacuum Formed Shapes come into play.

Offering unparalleled design flexibility and thermal efficiency, these customized components are the "secret weapon" for engineers looking to optimize heat containment in extreme environments.

What are Ceramic Fiber Vacuum Formed Shapes?

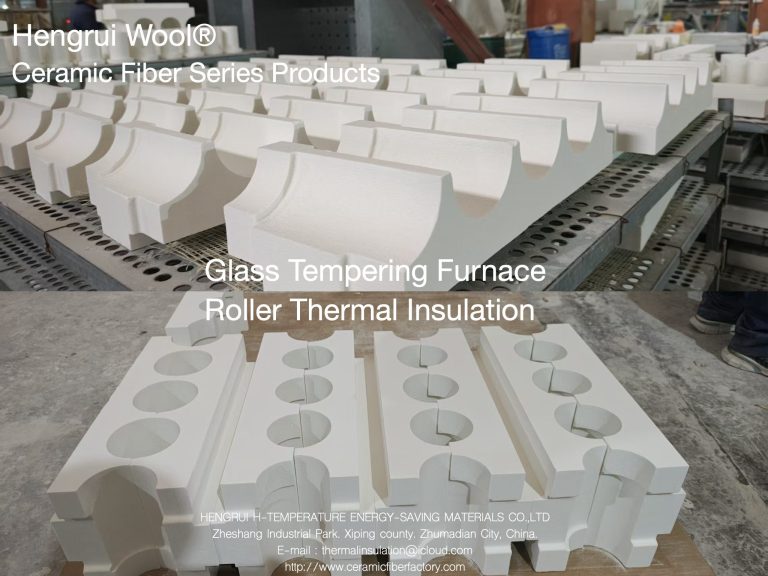

Ceramic fiber vacuum formed shapes are specialized refractory products manufactured from high-purity alumina-silica fibers. Using a unique vacuum suction filtration process, a slurry of fibers and inorganic/organic binders is formed into specific molds.

This process allows for the creation of lightweight, rigid, and highly insulating components that can withstand temperatures ranging from 1000°C to 1600°C.

1. Shape Diversity: Beyond the Rectangle

The most significant advantage of vacuum forming is the ability to move beyond flat surfaces. Because the material is formed in a mold, it can take on almost any three-dimensional configuration, including:

- Cones and Sleeves: Ideal for molten metal casting.

- Tubes and Cylinders: Perfect for laboratory furnaces and heating elements.

- Burner Blocks: Custom-designed to match specific flame patterns.

- Peep Holes and Flanges: Essential for kiln observation and structural joints.

- Elbows and T-junctions: For specialized piping and exhaust systems.

2. High Designability and Engineering Precision

Unlike traditional bricks or castables, vacuum formed shapes are highly machinable. They can be engineered with precise tolerances to fit snugly around complex machinery.

- Uniform Density: The vacuum process ensures consistent thickness and density throughout the piece.

- Low Thermal Conductivity: Their porous structure provides excellent insulation, significantly reducing energy costs.

- Low Heat Storage: These shapes heat up and cool down rapidly, improving furnace cycle times.

3. Fully Customizable for Every Application

Every industrial application has its own set of thermal and mechanical stressors. Customization is at the core of vacuum forming technology.

- Material Blends: We can adjust the ratio of alumina to silica or add polycrystalline fibers to meet specific temperature ratings.

- Surface Treatments: Depending on your needs, shapes can be treated with hardeners to increase resistance to high-velocity gases or molten metal erosion.

- Integrated Inserts: We can incorporate grooves for heating wires or holes for sensors directly into the design.

Key Applications

From aerospace to glass manufacturing, these shapes are utilized wherever standard insulation fails to meet the geometric requirements:

- Petrochemical: Heater linings and burner tiles.

- Metallurgy: Tundish covers, sprue bushings, and riser sleeves.

- Ceramics & Glass: Kiln car insulation and crown transition sections.

- Domestic Appliances: Combustion chambers for high-efficiency boilers.

Why Choose Our Vacuum Formed Solutions?

As a leading provider of refractory materials, we specialize in transforming your technical drawings into high-performance components. Our vacuum formed shapes offer:

- Excellent Thermal Shock Resistance: They won’t crack or spall under rapid temperature changes.

- Chemical Stability: Resistant to most corrosive agents and oxidation.

- Ease of Installation: Lightweight and easy to handle, reducing downtime during maintenance.

When your project demands more than just a "blanket" solution, Ceramic Fiber Vacuum Formed Shapes provide the precision, durability, and customization necessary to handle the heat. By choosing custom-engineered shapes, you are investing in energy efficiency, operational safety, and long-term cost savings.