Ceramic fiber modules are advanced refractory insulation products designed to simplify furnace construction, enhance thermal integrity, and improve energy efficiency. Anchor systems for Ceramic Fiber Module/Z-Block are crucial for ensuring the stability and reliability of these installations. With precise dimensions, excellent heat resistance, and easy installation, these modules have become a key component in modern industrial furnace linings.

At HENGRUI High Temperature Energy-Saving Materials Co., Ltd., we not only manufacture high-quality ceramic fiber modules but also design and produce specialized anchoring systems to ensure reliable installation and long-term furnace stability when using anchor systems for Ceramic Fiber Module/Z-Block.

What Are Ceramic Fiber Module Anchors?

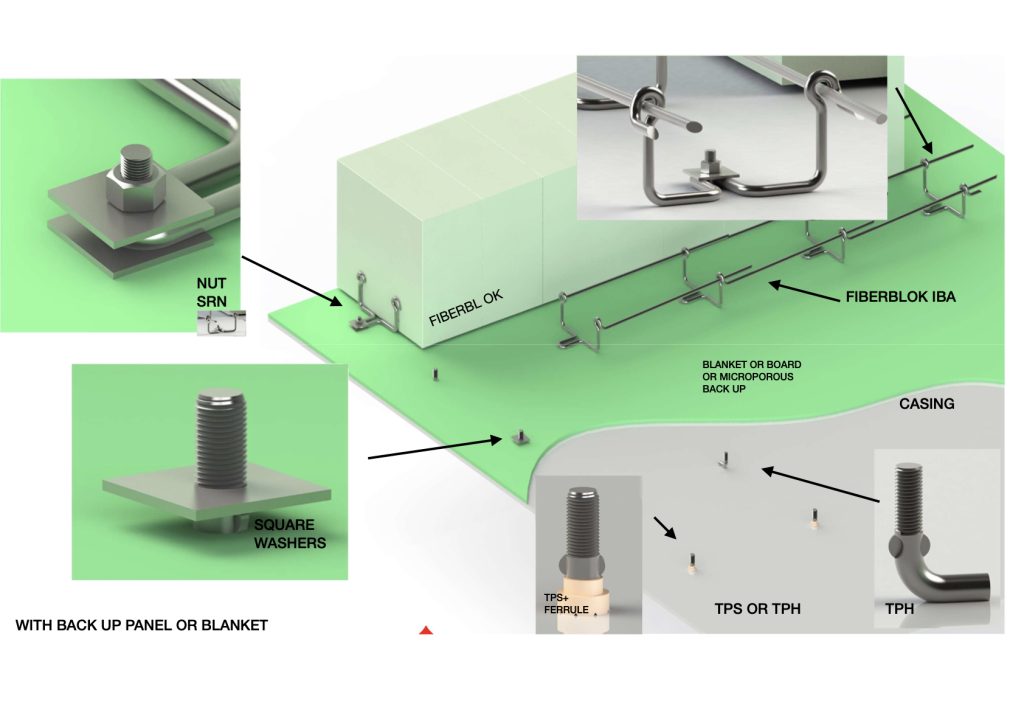

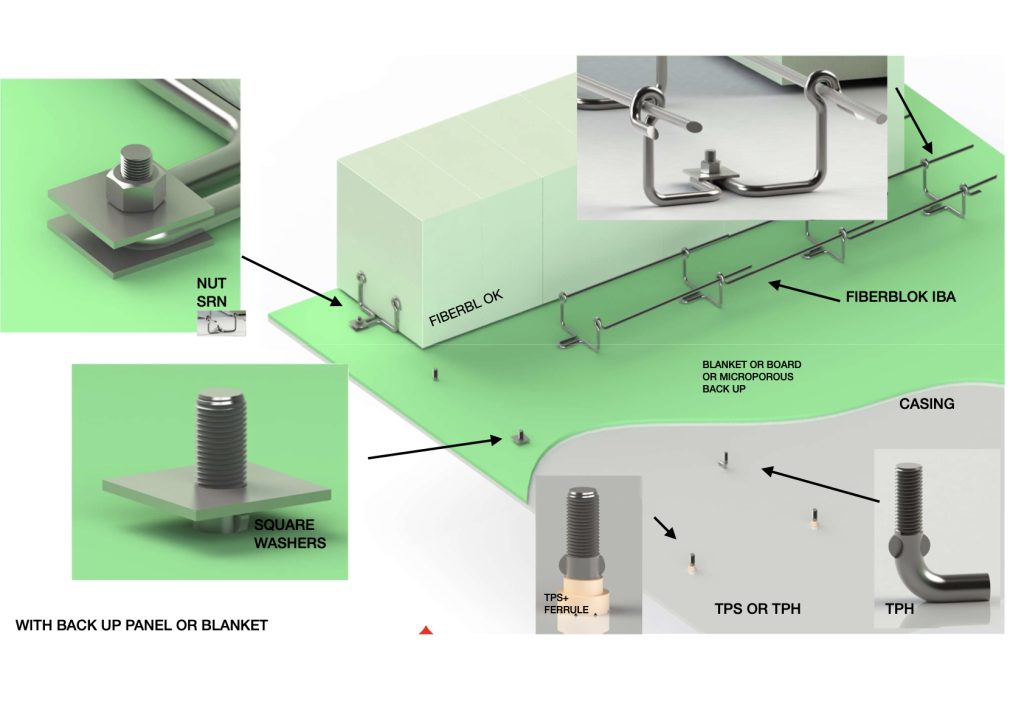

Anchors are metal fasteners that connect lightweight refractory materials—such as ceramic fiber modules, insulating bricks, or castables—to the furnace steel shell. They play a crucial role in maintaining the integrity of the insulation system under high-temperature and dynamic conditions, particularly in systems like those for Ceramic Fiber Module/Z-Block.

Depending on the furnace type, temperature, and atmospheric environment, different anchor designs and materials are used to achieve optimal performance and safety in anchor systems for Ceramic Fiber Module/Z-Block.

Common Types of Anchoring Structures

Specially designed for ceramic fiber modules, this type features an L-shaped steel base for firm attachment to the furnace wall. It provides excellent stability for folded and stacked modules, which is essential for systems like Ceramic Fiber Module/Z-Block.

1.M-Type anchor

This anchor fastener is made of high-quality stainless steel with excellent high-temperature and corrosion resistance. Its robust structure and easy installation design make it ideal for securing ceramic fiber modules, blankets, and refractory linings, ensuring a firm connection between the module and the furnace shell for long-term stable performance, such as in an anchor system for Ceramic Fiber Module/Z-Block applications.

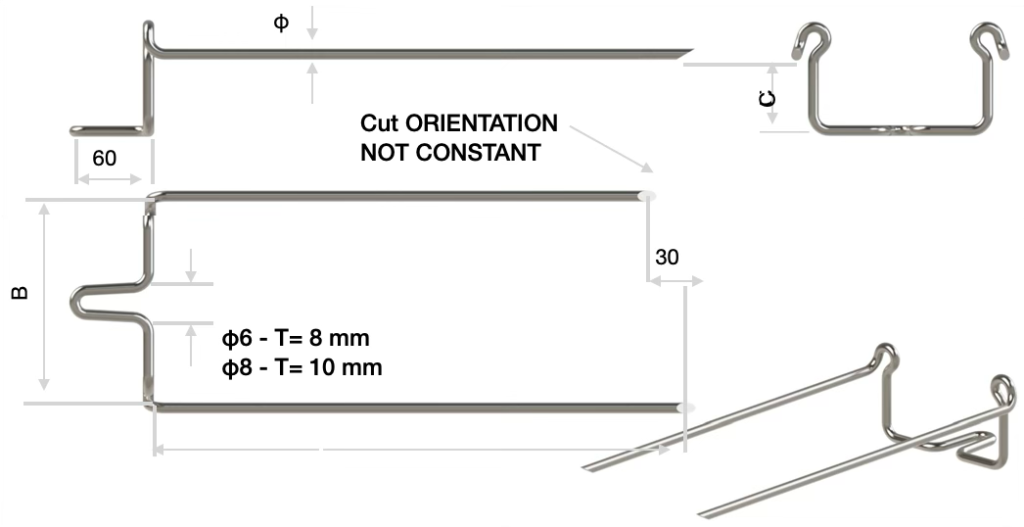

2.IBA-Type anchor

Customized Module Anchoring Solutions by Hengrui

At Hengrui, we proudly introduce our new generation of customized lining systems—designed to enhance both the thermal efficiency and structural integrity of industrial furnaces and kilns, incorporating anchor systems for Ceramic Fiber Module/Z-Block when needed.

These advanced modules deliver superior insulation performance through their homogeneous fibrous lining, ensuring consistent heat distribution and excellent energy retention across oven walls.

Engineered for high resistance to mechanical stress and thermal shock, our modules are easy and flexible to install on site. This is made possible by the integrated stainless-steel support tubes and our proprietary IBFork anchoring system, both designed and manufactured by IRIS. Such innovations are part of our commitment to anchor systems for Ceramic Fiber Module/Z-Block.

Our expert team works closely with each client to provide fully customized module and anchoring solutions, perfectly adapted to your operational requirements and environmental conditions.

IRIS – Innovation anchored in performance.

Installation Instructions

Material Selection

HENGRUI’s anchors are available in various high-temperature alloys:

- 304 Stainless Steel – for temperatures up to 800°C

- 310-310S Stainless Steel – for higher temperatures up to 1,000°C

Each anchor is precision-engineered, ensuring easy installation, high strength, and corrosion resistance even in reducing or oxidizing furnace atmospheres. This precision is especially important in anchor systems for Ceramic Fiber Module/Z-Block.

Application Fields

Our ceramic fiber modules and anchoring systems, including efficient anchor systems for Ceramic Fiber Module/Z-Block, are widely used in:

- Heat treatment furnaces (annealing, tempering, forging)

- Aluminum melting furnaces

- Glass annealing and melting kilns

- Ceramic sintering furnaces

- Hydrogen production and petrochemical furnaces

- Tunnel kilns, shuttle kilns, and roller kilns

- Steel ladle and cover insulation systems

With years of experience in refractory design, HENGRUI provides complete furnace lining solutions, including anchor selection, insulation structure design, and on-site installation services for complex thermal environments, including those requiring anchor systems for Ceramic Fiber Module/Z-Block.